Spiral Submerged Arc Welded Steel Pipe

| Outside Diameter (OD) | 219mm – 3500mm (8″ – 137″) |

| Wall Thickness (WT) | 5mm – 30mm |

| Length | 6m – 18m (Custom lengths available upon request) |

| Standard | API 5L (PSL1, PSL2), ASTM A252, ASTM A53, EN10219, GB/T 9711 |

The SSAW steel pipe is widely used in long-distance pipeline projects for the transmission of oil, natural gas, water as well as coal gas, etc, and also is used in all kinds of engineering, such as chemical industry, electric power, irrigation, construction, and piling, etc.

Production Description

SSAW (Spiral Submerged Arc Welded) steel pipe is the backbone of large-scale infrastructure. Manufactured by forming hot-rolled strip steel into a spiral shape and welding the seams using double-sided submerged arc technology, these pipes offer exceptional structural integrity and cost-efficiency for long-distance pipelines.

At Rayoung, we combine decades of manufacturing expertise with rigorous quality control to deliver SSAW pipes that withstand high pressure and harsh environmental conditions. Whether for water transmission, structural piling, or the oil and gas industry, our pipes are engineered to exceed international standards.

Specification

| Application: | Used for oil/gas/water transmission,construction & structure parts |

| Size: | OD: 219mm-4064mm |

| WT: 3.2mm-40mm | |

| Length: 5.8 /6 / 11.8 / 12 / 18 / 32 / 48m | |

| Pipe Standard: | API 5L PSL1/ PSL2 Gr.A Gr.B, X42, X46, X52, X60, X65, X70 |

| ASTM A53 ,Gr.A, Gr.B, | |

| ASTM A252 Gr. 1, Gr. 2, Gr.3 ASTM A500 | |

| AS /NZS 1163 , AS /NZS 1074 | |

| EN10219 ,EN 10217, etc. |

Standard

| Classification | Standard | Main Products | ||||||||||||||

| Line Pipe | API 5L PSL1/2 | Line pipe | ||||||||||||||

| Casing | API 5CT/ ISO 11960 PSL1 | Steel pipe for use as casing or tubing for wells of the petroleum and natural gas industries | ||||||||||||||

| Steel Pipe for Fluid Service | ASTM A53 | Black and hot-dipped galvanized, welded, and seamless steel pipe | ||||||||||||||

| BS EN10217-2 | Welded steel tubes for pressure purposes – delivery technical conditions – part 2: Electrically welded non-alloy and alloy steel tubes with specified elevated temperature properties | |||||||||||||||

| BS EN10217-5 | Welded steel tubes for pressure purposes – delivery technical conditions – part 5: submerged arc welded non-alloy and alloy steel tubes with specified elevated temperature properties | |||||||||||||||

| Steel Pipe for Ordinary Structure | ASTM A252 | Welded and seamless steel pipe piles | ||||||||||||||

| BS EN10219-1 | Cold-formed welded structural hollow sections of non-alloy and fine-grain steels – Part 1: Technical delivery conditions | |||||||||||||||

| BS EN10219-2 | Cold-formed welded structural hollow sections of non-alloy and fine-grain steels – Part 2: tolerances, dimensions, and sectional properties | |||||||||||||||

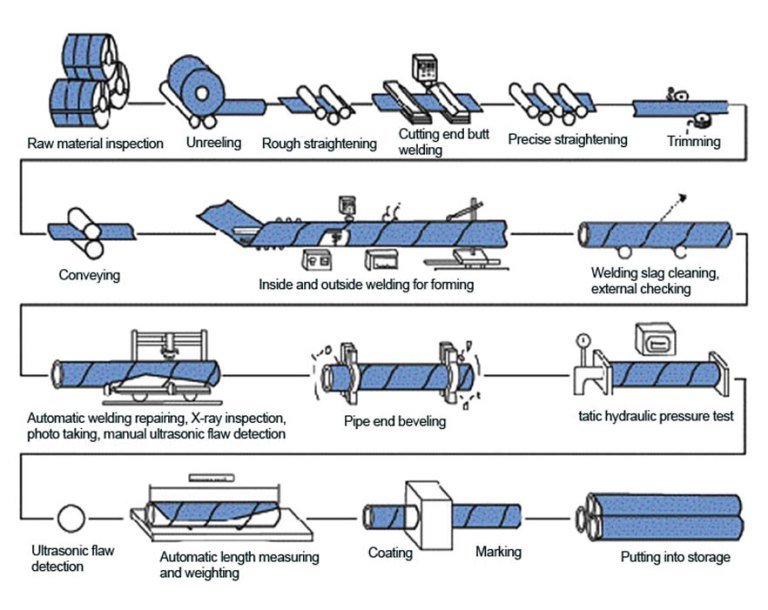

Technological process

Global Applications

Our SSAW steel pipes are trusted by engineers worldwide for:

- Water Supply Systems: Large-diameter mains and municipal drainage.

- Piling & Foundations: Bridge piers, port construction, and high-rise building foundations.

- Energy Transport: Low-pressure gas pipelines and thermal power plant circulation.

- Structural Projects: Heavy-duty steel columns for stadiums and airports.

FAQ

Q: Can SSAW pipes be used for high-pressure gas transmission?

A: While SSAW is excellent for water and low-to-medium pressure gas, for ultra-high-pressure gas mains, we recommend checking the specific API 5L PSL2 requirements which our factory can also accommodate.

Q: What is the maximum diameter you can produce?

A: We currently produce up to 3500mm OD, making us one of the few suppliers capable of supporting massive marine piling projects.

Q: How do you prevent corrosion for underground use?

A: We offer 3PE (Three-Layer Polyethylene) and FBE (Fusion Bonded Epoxy) coatings, which can extend the service life of the pipe to over 50 years in soil.

Cooperate with Rayoung, you will enjoy the following benefits.

Rayoung–A leading Butt Weld pipe fittings, flanges and steel pipes supplier& factory in China.

We’re here to help with your industry pipe fittings and flange needs. Rayoung has been in the business of industrial pipe fittings since 1983, and we’re confident we can help you find a solution more quickly, affordably, and with greater expertise than the competition.

We’d love to learn more about your project today!

Pre-sale Service

After-sale Service

Free Sample

Fast Quotation

Cerfifications

Test & Inspection

Customers say:

Talk About Your Needs

We respect your privacy and will not share your personal information with third parties or partners.