ASTM A234 WPB Buttweld Tee

The ASTM A234 WPB buttweld Tee is manufactured using seamless or welded pipes that conform to the ASTM A106 or ASTM A53 specifications.

The buttweld tee fitting is designed to withstand high-pressure applications and is ideal for use in the oil and gas, chemical processing, and power generation industries.

Production Description

Buttweld Pipe Tee is a type of pipe fitting that is T-shaped, having two outlets at 90° to the connection to the main line. It is a short piece of pipe with a lateral outlet. Pipe Tee is used to connect pipelines with a pipe at a right angle to the line. Pipe Tees are widely used as pipe fittings.

Standards : ASME / ANSI – B 16.9, ASTM A403 – ASME SA403, ASME B16.9, ASME B16.25, ASME B16.28, MSS SP-43.

Size: 1/2″NB TO 48″NB IN

Thickness : Schedule 5S, 10S, 20S, S10, S20, S30, STD, 40S, S40, S60, XS, 80S, S80, S100, S120, S140, S160, XXS and etc.

Form: Equal Tee, Unequal Tee, Reducing Tee, Barred Tee, Lateral Tee.

It is widely used in the petroleum, chemical industry, power plant, and food industry manufacturing, construction, shipbuilding, paper making, medicine, and other industries.

to join pipe sections together with other fluid control products like valves and pumps to create pipelines.

The ASTM A234 WPB buttweld Tee is manufactured using seamless or welded pipes that conform to the ASTM A106 or ASTM A53 specifications. The buttweld tee fitting is designed to withstand high-pressure applications and is ideal for use in the oil and gas, chemical processing, and power generation industries.

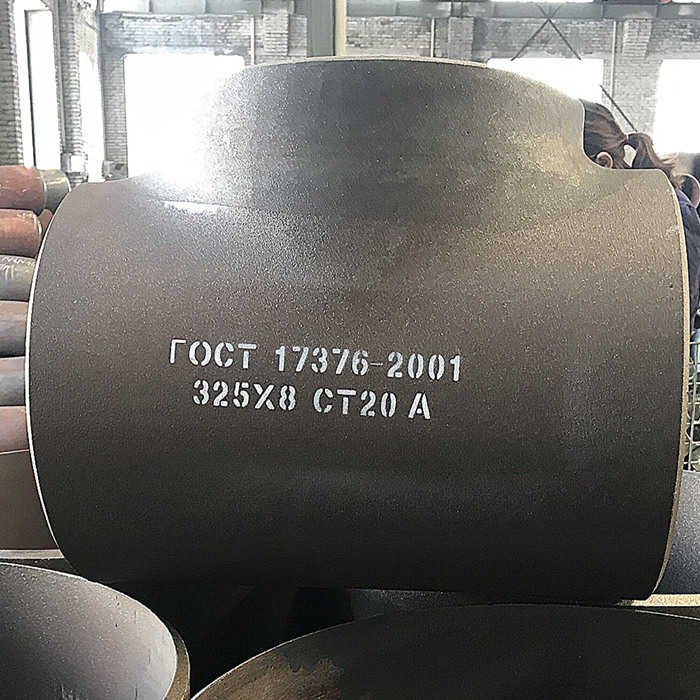

Buttweld Carbon Steel Tee Specification

| Technique | Cold Drawing, welding |

| Standard | ASTM DIN EN BS JIS GOST etc. |

| Size | DN 15-DN 2400, 1/2″ – 96″ |

| Thickness | 2MM-32MM, and customized thickness |

| Pipe Tee Ends | Beveling |

| Type | Equal Tee, Reducing Tee, Barred Tee, Lateral Tee |

| Surface Treatment | Sand Blast, Transparent Anti-rust Oil, PE/3PE anti-corrosion coating, other customized coatings |

| Material | Steel 20#, Q235, Q345, 16mN, 15CrMo, etc |

| Material in Stock | Carbon steel, Mild steel, LTCS, Alloy Steel |

| Package | Plastic bags, pallets, plywood case, etc |

| Production Time | 3-5 days for stock goods, 15-30 days for one container, more 10 days for one more container. |

| Application | Petroleum, Natural Gas, Water Disposal, Shipbuilding, Nuclear Energy, Chemical Engineering, Deckle, Electric Power |

Rayoung Supply Range

Standard: ASME B16.9, SH3408, HG/T21635, HG/T21631, SY/T0510

Size: 1/2″, 1″, 2″, 3″, 4″, 6″, 8″, 10″, 12″, 16″, 20″, 24″ to 60″

Schedule: Sch 20, STD, Sch 40, XS, Sch 80, Sch 100, Sch 120, Sch 140, Sch 160, XXS

End: Plain ( PE) or Bevel (BE)

Surface: Blasting and Painting, PE Coating, Hot Dip Galvanized.

Rayoung–A leading Butt Weld pipe fittings, carbon steel Butt Weld Reducer, butt weld elbow, butt weld tee, butt weld pipe elbow, butt weld cap & butt weld reducer manufacturer, exporter & wholesaler in China.

Why Choose Our Buttweld pipe fittings?

1. Strict Quality Control

2. Competitive Factory Pricing

3. Fast Delivery & Large Inventory

4. Customization Support

Cooperate with Rayoung, you will enjoy the following benefits.

Rayoung–A leading Butt Weld pipe fittings, flanges and steel pipes supplier& factory in China.

We’re here to help with your industry pipe fittings and flange needs. Rayoung has been in the business of industrial pipe fittings since 1983, and we’re confident we can help you find a solution more quickly, affordably, and with greater expertise than the competition.

We’d love to learn more about your project today!

Pre-sale Service

After-sale Service

Free Sample

Fast Quotation

Cerfifications

Test & Inspection

Customers say:

Talk About Your Needs

We respect your privacy and will not share your personal information with third parties or partners.