What is a Butt Weld Cap?

In industrial piping systems, the integrity of every connection is critical. While pipes transport the media, it is the fittings that control the flow and ensure safety. One of the most essential, yet often overlooked components, is the Butt Weld Cap.

Also known as a pipe cap or pipe head, this fitting is the industry standard for permanently sealing pipe ends. But what exactly is it, and why is it vital for sectors ranging from Oil & Gas to Power Generation?

What is Butt Weld Cap?

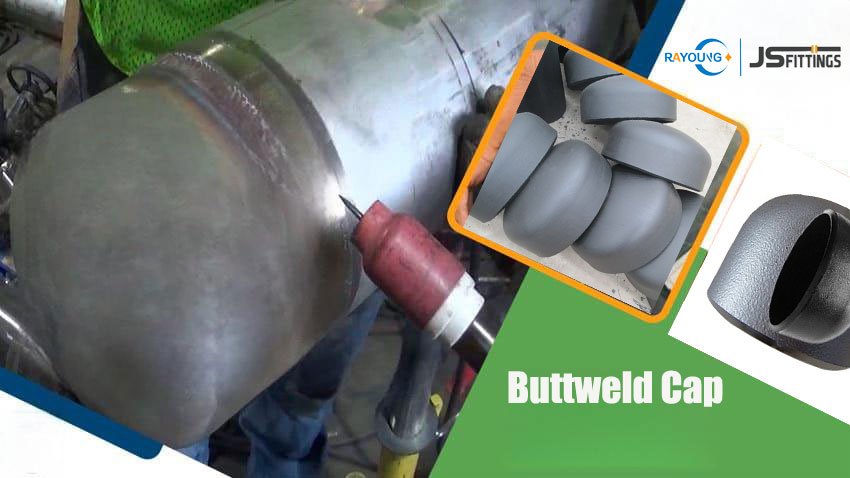

A Butt Weld end Cap is a pipe fitting designed to cover the end of a pipe, effectively acting as a permanent block. Unlike a blind flange (which is bolted and removable), a butt weld cap is connected via a full-penetration weld.

Shape & Fit: It is typically semi-ellipsoidal or circular, designed to match the outer diameter and wall thickness of the connecting pipe.

The Connection: The “Butt Weld” technique involves beveling the ends of both the cap and the pipe, placing them butt-to-butt, and welding the seam. This creates a joint that is often stronger than the pipe itself.

Why Materials Matter?

To withstand harsh industrial environments, these caps are engineered for resilience. They are manufactured from high-grade materials including:

- Carbon Steel

- Stainless Steel

- Duplex Steel

- Special Alloy Steel

These materials provide exceptional resistance to oxidation, acids, alkalis, and salt solutions, ensuring the cap lasts as long as the pipeline itself.

Core Functions: Prevents Fluid Leakage

The role of a butt weld cap extends beyond simply closing a hole. It serves two critical functions:

- Prevents Fluid Leakage

When transporting hazardous chemicals, high-pressure steam, or expensive hydrocarbons, “minor leaks” are not an option. The welded nature of the cap ensures a 100% leak-proof seal, preventing fluid or gas from escaping into the environment and guaranteeing system safety. - Contamination Control

The cap acts as a shield. It prevents dust, moisture, debris, and other external impurities from entering the pipeline. This is vital for applications requiring high purity, protecting downstream equipment from damage and the media from contamination.

Where are Butt Weld Caps Used?

Because of their durability and high-pressure tolerance, butt weld caps are the go-to solution for end-of-line isolation in major industries:

- Oil & Gas: Essential for sealing hydrocarbon transport lines and isolating pipeline sections during maintenance.

- Water Supply: Critical for maintaining network pressure and preventing groundwater or soil contamination in potable water systems.

- Power Generation: Used in extreme environments, such as steam headers and heating furnace pipelines, where high temperature and pressure are constant.

- Chemical Processing: Ensures the safe containment of aggressive chemicals, complying with strict environmental and safety regulations.

- Construction & HVAC: Guarantees airtight and watertight seals in plumbing and climate control systems.

- Shipbuilding: Ensures the integrity of the complex piping networks inside marine vessels.

Key Benefits: Why Choose Butt Weld Caps?

When designing or maintaining a piping system, butt weld caps offer distinct advantages over other sealing methods:

- Permanent Integrity: The welded joint handles stress, vibration, and pressure fluctuations better than threaded or bolted fittings.

- Streamlined Internal Flow: The internal shape of the cap is contoured to match the pipe, creating a smooth transition. This minimizes turbulence and prevents sediment accumulation at the dead end of the line.

- Space Efficient: Butt weld caps are compact and do not require the extra space needed for flange bolts.

- Maintenance Isolation: They allow engineers to permanently close off specific sections of a pipeline system to perform maintenance elsewhere without shutting down the entire operation.

Looking for reliable piping solutions?

Ensuring your pipeline is safe, efficient, and leak-free starts with the right fittings. Whether you are dealing with high-pressure steam or chemical transport, the Butt Weld Cap is your first line of defense against leaks and contamination.

Rayoung is a leading butt-weld pipe fittings factory & supplier in China. Welcome to contact us if you need butt-weld pipe caps.

Emails: info@hb-steel.com

Tel/whatsapp: +86-18003119682