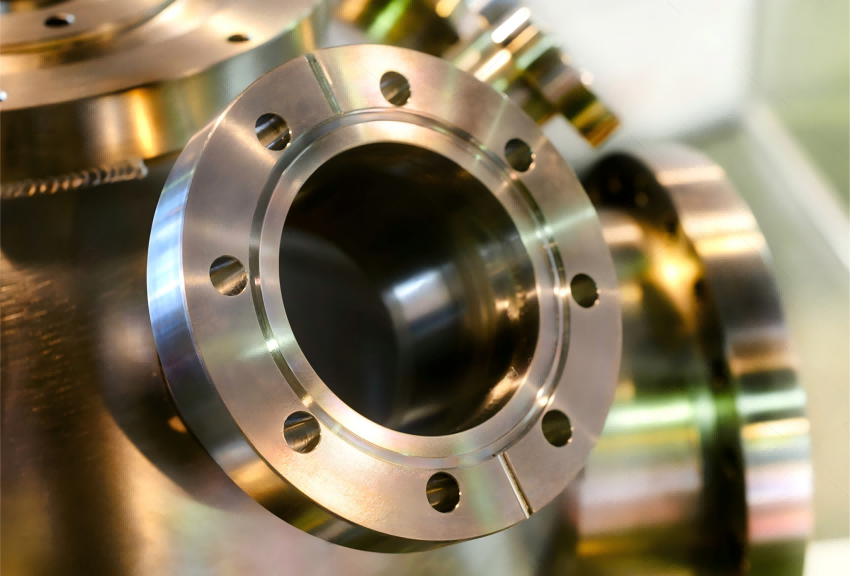

Flanges play a critical role in piping systems across various industries, providing essential connections that ensure fluid transport is both efficient and secure. Among the numerous flange types available, six stand out for their widespread use and performance: weld neck, slip-on, socket weld, lap joint, threaded, and blind flanges. Understanding the applications and advantages of each can guide you in selecting the ideal flange for your specific needs.

1. Weld Neck Flanges

Usage and Applications: Weld neck flanges are designed for high-pressure applications, making them ideal for critical services in the oil, gas, and chemical industries. They are welded directly onto the pipe, which allows for smooth flow and reduced turbulence.

Advantages: Their long neck provides reinforcement and reduces stress concentration at the base of the flange, ensuring durability under pressure.

Limitations: The installation process is more complex and time-consuming, requiring skilled welders to achieve a proper fit.

2. Slip-On Flanges

Usage and Applications: Slip-on flanges are versatile and easier to install than weld neck flanges, suitable for low-pressure applications where frequent disassembly is not a requirement.

Advantages: They are less costly and allow for simple alignment with the pipe during installation, making them user-friendly.

Limitations: Slip-on flanges have a lower strength compared to weld necks, making them less suitable for high-pressure environments.

3. Socket Weld Flanges

Usage and Applications: These flanges are commonly used in small-diameter, high-pressure piping systems. They are popular in chemical processing and hydraulic systems.

Advantages: The socket weld design provides a smooth bore and better flow characteristics, reducing the risk of leakage.

Limitations: They are not recommended for larger pipe sizes due to stress concentration in the socket area.

4. Lap Joint Flanges

Usage and Applications: Ideal for systems requiring frequent disassembly for inspection or maintenance, lap joint flanges are often used in conjunction with stub ends.

Advantages: The design allows for ease of alignment and assembly, accommodating for minor misalignments without additional stress on the piping.

Limitations: The lap joint itself does not provide any structural strength, relying on the stub end for support.

5. Threaded Flanges

Usage and Applications: Used predominantly in low-pressure, non-critical applications, threaded flanges are common in utility systems and domestic piping.

Advantages: They allow for easy assembly and disassembly without welding, making them ideal for temporary connections or maintenance.

Limitations: Threaded connections are susceptible to leakage, thus unsuitable for high-pressure or high-temperature applications.

6. Blind Flanges

Usage and Applications: Blind flanges are used to terminate the end of a piping system, commonly in testing and repair operations within oil, gas, and water supply systems.

Advantages: They provide a robust seal and are easy to install and remove, facilitating system access.

Limitations: While effective at sealing, they do not allow for fluid flow, necessitating complete removal for access to the piping system.

Conclusion: Selecting the Right Flange

Choosing the appropriate flange type depends largely on your specific project requirements and conditions. For high-pressure applications, weld neck flanges offer superior strength. Slip-on and socket weld flanges are excellent for lower-pressure systems, balancing ease of installation with performance. Lap joint flanges provide flexibility for systems requiring frequent maintenance, while threaded flanges are perfect for temporary installations. Finally, blind flanges are essential for securely sealing piping systems during testing and maintenance.

In conclusion, understanding the unique characteristics and applications of each flange type can help you make informed decisions, ensuring the optimal performance and longevity of your piping systems.

#JSFITTINGS #RAYOUNG #STEELPIPE #FLANGE #STEELPIPE #MADEINCHINA #MANUFFACTURER #FACTORY #PIPEELBOW #PIPE REDUCER #INDUSTRYFLANGE

Email: admin@jsfittings.com

Whats App: 008618003119682