China Forged Steel Flanges Suppliers

Forged Steel Flange Manufacturer & Supplier for Active engineering trading and stockist, industry Projects.

DIN, ASME and Gost standards availabie.

Fast delivery and OEM support

Brands We Cooperation

Premium Flanges For Industry Pipeline System

Looking for world-class flanges for your industry? We offer premium forged steel flanges with unmatched strength and top-notch performance.

Blind Flanges

Blind flanges temporarily or permanently block the flow of fluids or gases in a pipeline. It is beneficial when a pipeline needs to be disconnected from the rest of the system for maintenance, repairs, or other purposes.

Plate Flanges

A plate flange is a flat, circular disc welded to a pipe’s end enabling the flange to be bolted to another pipe. It is often referred to as flat flange, plain flange and flange slip, etc. It is usually used in fuel and water pipelines.

Weld Neck Flanges

A weld neck flanges transfers stress to the pipes, lessening the high-stress concentration at the bottom of the flange. This attribute of weld neck flanges makes them suitable for the oil and gas industry.

Slip-On Flanges

Slip-on flanges on the pipe and connect without utilizing additional tools for installation. The design of slip-on flanges allows direct and secure pipe connections that can withstand high pressure and temperature conditions without leaking or bursting

Threaded Flanges

A threaded flanges connects a device securely to a pipe without welding. Threads create a secure and leakage-free connection between the flange and the pipe. Threaded flanges work well for fixing equipment quickly.

Socket-Weld Flanges

Socket-weld flanges are suitable for smaller-diameter pipes and operate in lower-pressure/temperature systems. Insert the pipe into the female socket of socket-weld flanges, and then a fillet weld is used around the top to create a connection. It allows a seamless flow of liquid or gas in the pipe.

Table Of Contents

- Why wholesale steel flange from us?

- International standards that hot saled

- Estimated wholesale price

- Estimated manufacturing and shipping times

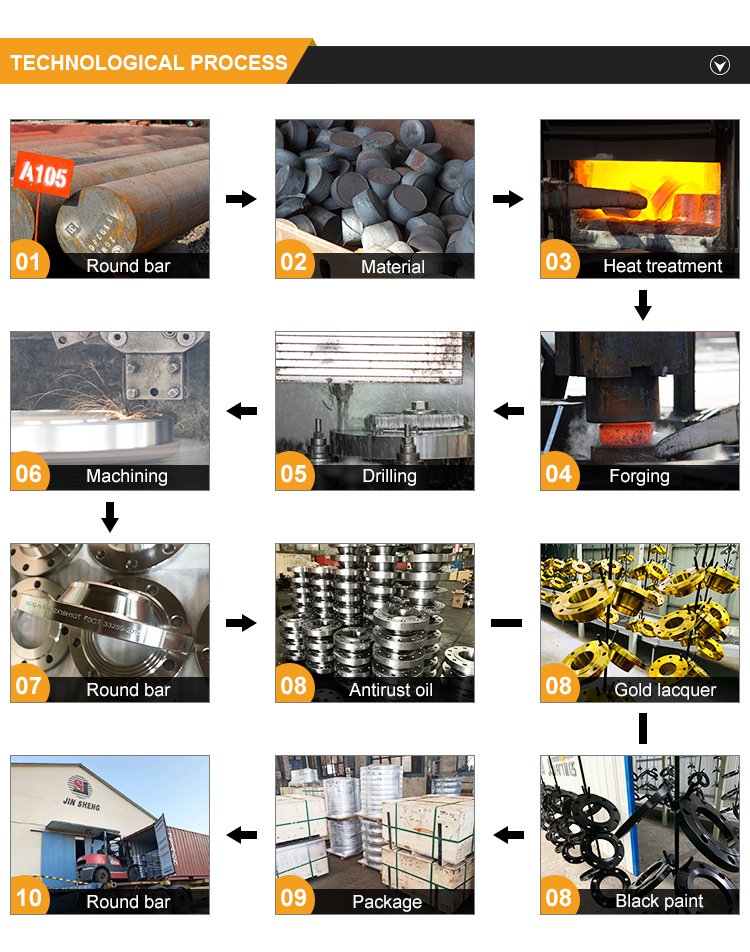

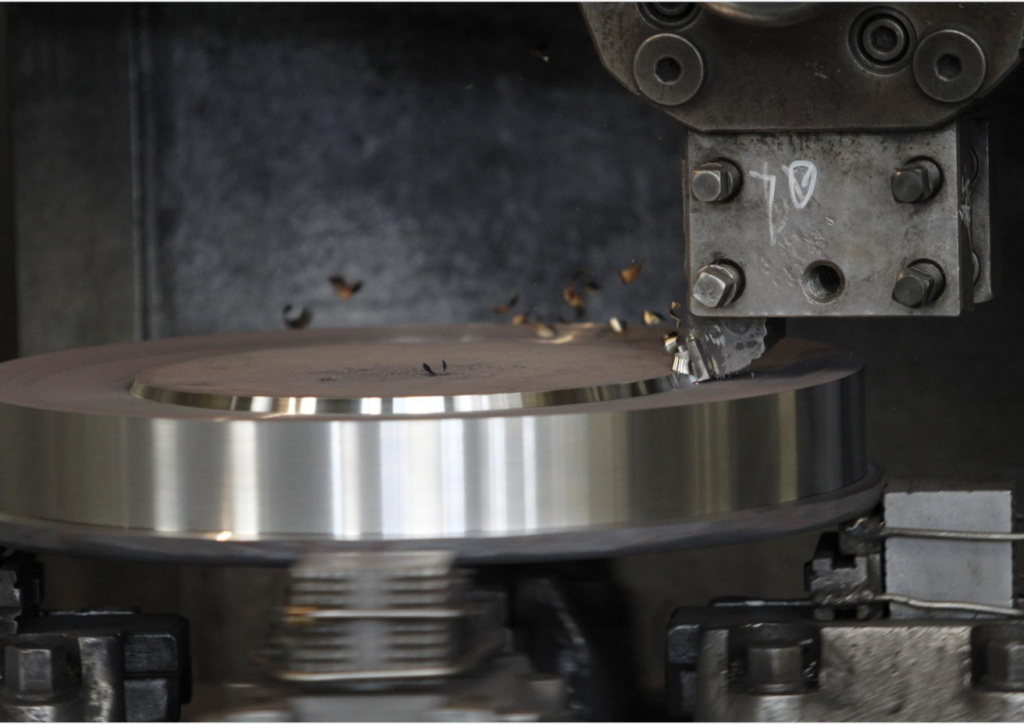

- The whole process of forged flanges

- The knowledge about forged flanges

- The common pitfalls of purchase

- Why choose RAYOUNG flange

- FAQs about RAYOUNG forged flanges

- Contact RAYOUNG to Start Your Business

Click the content you want to know

To save you time, we have also prepared a PDF version of a purchase guide, only leave your email and you will get the download link immediately.

Why Choose RAYOUNG Flange

As suppliers of forged steel flanges, we produce international standard flanges for low, medium, and high-pressure gas, water, and oil applications—capable of withstanding up to 4 tons per square inch (psi). We also offer customized dimensions built to endure extreme temperatures and harsh chemicals without fail.

Our industrial steel flanges in diameters meet the demands of heavy-duty applications in oil & gas, petrochemical, power generation, and large infrastructure projects.

With full in-house capabilities—from forging to machining and testing—we ensure dimensional precision, structural integrity, and international standard compliance.

- Your inquiries will be replied within 2 hours

- New quotation list will arrive you within 24 hours

- 36-year production experience

- All orders will be executed strictly according to the contract

- Automatic production lines supply quality goods in shorter time

- We will update you the production progress in time

- Professional exporting team

- Priority booking stand-on vessel

- Free documents for customs clearance and import tariff reducing

- Long warranty time and worry-free after-sale service

- We provide various types of standard and custom forged steel flanges in all sizes and standards.

International Standard Hot Selling Products

A flange standard lays down the dimensions, surface finish, facing type, marking, material, and technical specifications for flanges.

We produce high-quality steel flanges that meet various international standards, such as:

- Material: Carbon Steel, Alloy steel and stainless steel

- OEM availiable: customized data, surface treatment, mark and package

- Factory price: no middle man

- Qulified products: quality inspection and lab test

- ISO 9001 approved

The daily output of the forged flanges is more than 30 tons, automatic painting lines are running day by day.

- Material: Carbon Steel, Alloy steel and stainless steel

- OEM availiable: customized data, surface treatment, mark and package

- Factory price: no middle man

- Qulified products: quality inspection and lab test

- GOST- R Approved

Familiar with GOST standards and the different demands of the markets. All your special demands can be matched.

- Standard specification

- OEM availiable

- Factory price

- Qulified products

- CE approved

The property and material department manages the purchase of raw materials and arranges order production so as to ensure your exact delivery date.

Wanna dig deeper in industrial flanges?

Industries We Serve

Explore diverse industries where flanges truly shine – Rayoung offers steel flange solutions for all.

Petrochemical Treatment And Processing

In chemical processing plants, flanges connect pipes and other equipment, ensuring the smooth flow of hazardous chemicals and petroleum products without any leakage.

Industrial Pumps And Manufacturing Systems

Flanges are vital in this industry, ensuring the secure connection of pipes and pumps without any leakage in the manufacturing sector.

Large-Scale Pipe Systems And Waterworks

Flanges connect pipes and maintain the integrity of gigantic systems in the mining and construction sectors and municipal water delivery systems.

Nuclear Power Plants

A flange is essential for the system’s safety in the pipeline engineering of nuclear power plants. The main form of its failure is corrosion.

Heat Exchangers And Systems

Heat exchangers experience thermal expansion. Flanged connections can adapt this movement, preventing pressure on the components and reducing the risk of damage or failure.

Power Generation

Flanges join steam and water pipes, assuring a secure transport of fluids in boilers, turbines, and condensers in power plants.

Estimated Cost Analysis For Flanges

As suppliers of forged flanges, please note that the final cost depends on the customized services you require, the specifications of the raw materials used, applicable national regulations, and transportation distance. For example, booking a tall container of products may influence pricing based on these factors.

OD: 4" Pressure: class 900 Approximate weight: 23.2kg/piece Quantity: 1207 pieces Price:

$30,000

from the export port to the destination port

$4,300

from the export port to the destination port

$4,300

Insurance cost; Customs clearance fee; Import tax; Transportation costs from the port to your warehouse

$1,000

The Process Flow& Duration Estimation

The whole process from inquiry to cargo arrival will take a long time, now we provide you with a reference time according to the regular process

Step 1: Quotation and negotiation (7-15 days)

We are always online 7 x 24 without any special circumstances. Your inquiry will be answered within 2 hours and you will receive a detailed quote for your inquiry within 12 hours.

Since 2020, due to the epidemic and international trade situation, the prices of steel raw materials in China fluctuate frequently and are on an overall upward trend. Therefore, if your purchase plan is real, we recommend you sign the contract and arrange the prepayment as soon as you agree with the final price with the producer.

Step 2: Sampling (4-10 days)

If necessary, we will provide you with free samples for quality testing. You only need to pay for the courier cost.

Some small-sized fittings are in stock, for DN 50 or more samples need to wait for about 3 days, usually, the courier will deliver the samples to you in 4-10 working days.

Step 3: Prepayment (within 7 day)

Regardless of the country, it usually takes 1-7 business days from the time you arrange the bank transfer to the payment arrives.

Step 4: Bulk Manufacturing (15-30 days)

After the advance payment arrives, the factory starts to prepare raw materials, quality inspection, and bulk manufacturing. It takes 15-30 days to complete a container of goods.

Step 5: Shipping ( 7-30 days)

After the goods have been produced, inspected, and packed, time needs to be reserved for booking and shipping.

Delivery – Loading – Discharging – Customs Declaration – Shipping – Customs Clearance – Unloading – Dispatch

Want to know how to compress lead times?

Contact us directly to get the right solution for your project. The more comprehensive the information you provide, the more accurate our quotations and delivery times are.

The Common Pitfalls When Purchasing

During the cooperation with more and more customers from different countries, we noted there are some pitfalls that often happen, so we collected the pitfalls together and wish to make your business easier.

Quotation validity,As prices fluctuate frequently. It is essential to negotiate prices in good time and to update them if an order has not been placed for more than a month.

Pricing Terms.

Under CIF contracts, the seller assumes responsibility for costs and liabilities until the shipment arrives at the destination, at which time the risk is transferred to the buyer.

Under FOB contracts, the buyer is responsible for shipping and other costs, as well as insurance as soon as the goods are loaded onto the vessel and during the voyage.

Under DDU contracts, the seller is responsible for ensuring goods arrive safely to a destination; the buyer is responsible for import duties.

Under DDP contracts, the seller must cover duties, import clearance, and any taxes.

In the contract, the delivery time commonly means the production time of your order. The time of the goods arrive your warehouse is aleo affected by the Vessel Schedule.

More advice is being updated……

A Brief Self-Nomination, Why Choose RAYOUNG Flange?

Founded in 1983, the RAYOUNG factory began by producing hot-pushed elbows and casting flanges, eventually expanding into a wider range of fittings and forged flanges. As dedicated suppliers of forged flanges, we’ve grown into a major fittings and flange company in China, now generating over $17,000,000 in annual sales. That’s right—you can rely on us!

The professional manufacturing capacity of RAYOUNG strongly guarantees high-quality products, competitive prices, and a short delivery time.

Still doubtful? Here are other reasons why we're your best bet:

- 36-years experience in manufacturing and supplying carbon steel seamless and welded pipe fittings and forged flanges.

- We're ISO, CE and GOST-R-certified; we're 100% legit.

- More than 100 happy customers worldwide. We have made products for companies in Russia, Thailand, UAE, Oman, Nigeria, etc.

- We're expanding fast. We currently have 5+ production lines and 100,000 square feet of factory space ready to serve you.

- Qualified products. Experienced QC team and strict QC process to ensure your export quality.

- We're fast and responsive. Connect with us on our site and we'll get back to you within 2 hours.

The FAQs About RAYOUNG Flange

Where is your factory?

Factory of RAYOUNG is in the base of Chinese pipe fittings, Yanshan county, Cangzhou City, Hebei Province. Contact us to get the visit brochure.

Which products do you mainly produce?

Carbon steel pipe fittings and flanges in the standard of ASME, GOST, EN, DIN, SANS, JIS, etc.

Do you manufacturer all size in house?

No, pipe fittings in size of DN200-DN720, medium and low pressure flanges in size of DN15-DN2000 are produced by ourselves, and the rest of the products are produced by brother factories.

What's your annual production?

The output is 1000 tons / month, almost export of 35-40 containers per month, annual output more than10000 tons.

How can I get your price list?

The rale price is based on the size, thickness, surfacetreatment, material, standard, quantity and destination. If you don't have a purchase plan, we can supply you a FOB price based on 1 container for reference.

Do you have distributors in my country?

We have stable distributors in Russia, Thailand, UAE, Nigeria, South Africa, Iran and other countries. If you can't import by yourself, we will be glad to introduce you to our customers.

Which payment terms are acceptable for you?

90% of our orders are paied in T/T USD, 30%-50% in advance, and the balance before shipment, or against the copy of BL. L/C, cash, Western Union are also acceptable.

How long is your warranty time?

The warranty period for regular carbon steel products is 1 year, and the normal use time is over 3 years. The warranty period for special products can reach more than 5 years.