Threaded Flange

Forged steel Threaded flanges feature tapered internal threads for quick connection to external pipe threads, offering the significant advantage of weld-free installation.

Size Range: Stocked from 1/2″ to 8″; NPT threads available up to 24″ upon request.

Ratings: Pressure classes from 150# to 1500#.

Material Standards:

Carbon Steel: ASTM A105

Stainless Steel: ASTM A182 (Available in 304L and 316L)

Pressure Classes: A comprehensive range from 150# to 1500#.

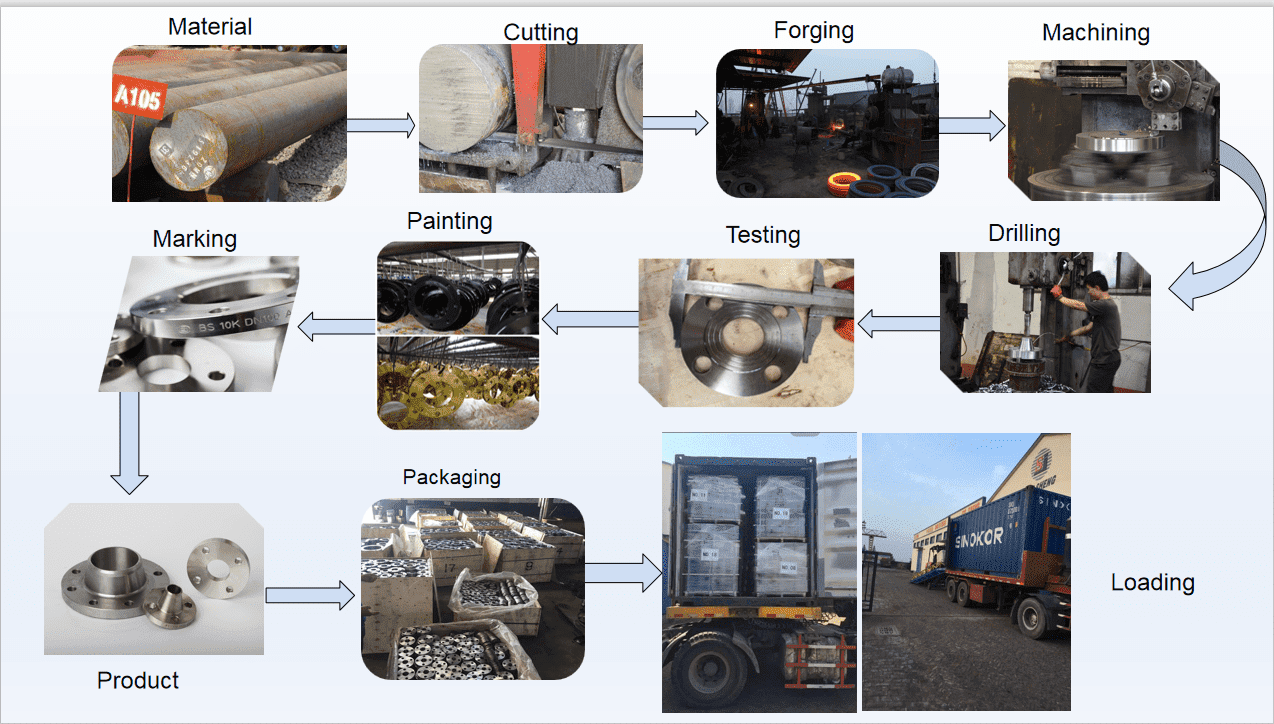

Production Description

What is a threaded flange?

Forged steel threaded flanges, also sometimes referred to as companion flanges/screw flanges / NPT flanges, contain a female NPT thread in the center for connection to male NPT threaded piping.

In most refineries, manufacturing shipyards, and facilities, the highly explosive nature of the materials moved through the pipeline prohibits welding. A threaded flange is a suitable option for assembling pipelines in this environment.

Although the threaded flange design is available in various sizes and pressure ratings, it is primarily used for small-sized piping systems. Its usage is also typically restricted to non-toxic systems, low-pressure systems, and low-temperature systems. ½ inch to 2-inch size threaded flanges are much more common than sizes of 2 inches and above. Due to their lower pressure applications, threaded flanges use flat and raised faces only. They are not suitable for high-temperature applications because the thread geometry would distort, which often leads to leakage.

The major advantage of threaded flanges is that they can be connected to a pipe without the need for welding. Forming joints without needing to weld is a considerable advantage, and is essential in some locations and industries, e.g., explosive areas (Ex-rated areas) such as petrol stations, hexane plants, stores with flammable fluids etc.

If no welding is required, a potential source of ignition is removed.

Another advantage is that it is quicker and easier to assemble and disassemble a threaded flange joint than a welded flange joint.

Application

The common ways you could use these flanges are:

- Useful in highly explosive areas

- Useful in applications where it is hazardous to do welding

- Flanges are highly economical and help save time

- Useful in the piping applications of small diameter

- Can be fitted to various pipe sizes without the need for welding

- Useful in situations where extreme pressure is present, and post-weld treatment is not an option

Explore Our Range of Industrial Pipe Flanges and Solutions

As a trusted steel pipe fittings and flanges manufacturer, RAYOUNG offers a comprehensive range of products engineered to meet international standards, including:

Standards Complied With:

ASME、ANSI,gost, EN, BS, SANS, DIN, JIS.

Material :

Carbon Steel (ASTM A105, A350 LF2)

Stainless Steel (ASTM A182 F304/F316)

Alloy Steel (ASTM A694 F42-F70)

Duplex & Super Duplex (ASTM A182 F51/F53/F55)

Nickel Alloys (Inconel, Monel, Hastelloy)

Coated flange:

General coated flange: Black Painting, Anti-rust Oil, red Painting, Gold Painting

Specially coated flange: Epoxy coated flange, Galvanized flange, PP coated flange

The production process of the Rayoung threaded flange

Production of every flanges follows precise manufacturing processes to achieve leak-proof connections while strengthening durability and performance stability with high-pressure systems.

Cooperate with Rayoung, you will enjoy the following benefits.

Rayoung–A leading Butt Weld pipe fittings, flanges and steel pipes supplier& factory in China.

We’re here to help with your industry pipe fittings and flange needs. Rayoung has been in the business of industrial pipe fittings since 1983, and we’re confident we can help you find a solution more quickly, affordably, and with greater expertise than the competition.

We’d love to learn more about your project today!

Pre-sale Service

After-sale Service

Free Sample

Fast Quotation

Cerfifications

Test & Inspection

Customers say:

Talk About Your Needs

We respect your privacy and will not share your personal information with third parties or partners.