Socket Weld Flange/SW Flange

Material Standard:

Carbon steel ASTM A105, ASTM A350 LF1/2, ASTM A181

Alloy steel ASTM A182 F5, F9, F11, F22, F91

Stainless steel ASTM A182 F304/L, F316/L

Outer Diameters: 1/2 inch to 24 inch, up to 2500#

Special made: 24” to 60”, up to 900#

Wall Thickness: Schedule 40 to 160

Pressure Ratings: Class 150 to Class 2500

Face Type: RF, RTJ

Production Description

In the demanding environments of oil, gas, and chemical processing, connection integrity is non-negotiable. Socket Weld Flanges (SW Flanges) are engineered to provide an airtight, robust connection for high-pressure systems where space is limited, and leakage prevention is critical.

At Rayoung, we manufacture industrial socket weld flanges that meet ASME/ANSI B16.5 standards, ensuring your infrastructure remains secure under the most extreme operating conditions.

What is a Socket Weld Flange?

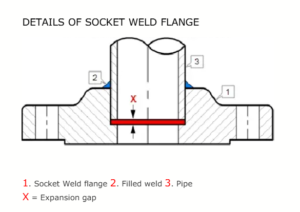

A Socket Weld Flange (SW Flange) is a specialized pipe flange characterized by a recessed area—or a “socket”—within the flange bore. This internal shoulder acts as a physical guide to set the insertion depth of the pipe.

Unlike a slip-on flange, the pipe is inserted into the socket until it hits the shoulder, then retracted slightly (typically 1/16”) to allow for thermal expansion during welding. The connection is then secured with a single fillet weld on the outer side.

Socket Weld Flanges are ideal for both low-pressure and high-pressure applications. They can withstand much higher pressures than other styles of flange, making them suitable for nearly any application, providing an airtight connection between pieces of piping or tubing.

Socket Welded Flange Face Types

Socket welded flange face types, including RF type and RTJ type, are used with other types of welding flanges (slip on, weld neck, or blind flange).

Advantages

1. Socket weld flange could replace a threaded flange to minimize the risk of leakage.

2. No need to bevel before welding.

3. Welding work outside of the pipe will not penetrate the pipe bore

4. It offers the same internal pressure capacity as slip-on flanges while improving fatigue resistance.

Do Socket Weld Flanges Have a Schedule?

Yes. To ensure a seamless flow and maximum structural integrity, Socket Weld Flanges must be specified with a pipe schedule that matches the wall thickness of the pipe they are being connected to.

When ordering, the internal bore of the SW flange is machined to match the inside diameter (ID) of a specific pipe schedule (such as Sch 40, Sch 80, or Sch 160). This creates a flush transition between the flange and the pipe, preventing any “step” that could cause flow resistance or corrosive buildup.

Pressure Ratings: Typically available in Class 150, 300, 600, 1500, and up to 2500.

Material Matching: We offer these in Carbon Steel (A105), Stainless Steel (F304/316L), and various Alloy Steels to suit your specific piping schedule and chemical compatibility.

How to Order Socket Weld Flanges?

To ensure your order is processed accurately and the flanges fit your project specifications perfectly, please provide the following technical details:

Nominal Pipe Size (NPS): Identify the pipe size (e.g., 1/2″, 1″, 2″).

Pressure Class: Specify the required rating (e.g., 150#, 300#, 600#, 1500#, 2500#).

Pipe Schedule: This is crucial for SW flanges. Indicate the schedule of the pipe being used (e.g., Sch 40, Sch 80/XS, Sch 160) so we can match the internal bore.

Material Grade: Specify the material (e.g., ASTM A105 for carbon steel, A182 F304/F316 for stainless steel).

Facing Type: Indicate the flange face type, such as Raised Face (RF) or Ring Type Joint (RTJ).

Standard: Confirm the manufacturing standard (e.g., ASME B16.5, DIN, or EN).

Why Choose Our Factory for Your SW Flange Needs?

As a specialist industrial flange manufacturer, we understand the needs of overseas stockists and terminal O&G contractors. Our socket weld flanges offer:

Superior Pressure Resistance: Designed to withstand significantly higher pressures than slip-on or threaded flanges.

Precision Machining: Our CNC-machined shoulders ensure perfect pipe alignment and easy welding.

Airtight Reliability: Optimized for critical applications where zero-leakage is mandatory.

Certified Quality: Every flange comes with a Mill Test Certificate (MTC) according to EN 10204 3.1.

Whether you are replenishing your inventory or sourcing for a large-scale oil and gas project, our team is ready to provide a competitive quote and technical support.

Cooperate with Rayoung, you will enjoy the following benefits.

Rayoung–A leading Butt Weld pipe fittings, flanges and steel pipes supplier& factory in China.

We’re here to help with your industry pipe fittings and flange needs. Rayoung has been in the business of industrial pipe fittings since 1983, and we’re confident we can help you find a solution more quickly, affordably, and with greater expertise than the competition.

We’d love to learn more about your project today!

Pre-sale Service

After-sale Service

Free Sample

Fast Quotation

Cerfifications

Test & Inspection

Customers say:

Talk About Your Needs

We respect your privacy and will not share your personal information with third parties or partners.