Slip on Flange

Standards: ASME B16.5, ANSI B16.47, EN1092-1, JIS B2220, DIN 2576.

Pressure Classes: Class 150, 300, 600, 900, 1500, 2500; PN6 to PN160.

Materials: Carbon Steel (A105, A350 LF2), Stainless Steel (F304/304L, F316/316L), Alloy Steel.

Quality Guarantee for Large Projects:

We understand the requirements of terminal users in the Oil, Gas, and Power industries. Every Slip-On flange undergoes 100% visual and dimensional inspection.

Production Description

What is a slip-on flange?

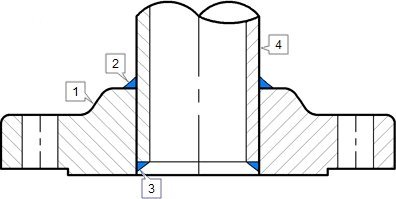

Slip-on flanges, also known as ‘hubbed flanges’, have a hub with a very low profile. The so flange is usually connected to a pipe by two fillet welds (one outside the flange and one inside the flange). Slip-on flanges are produced in many sizes and are favoured for lower-pressure applications.

They are called “slip-on” because they can be easily slipped onto the end of a pipe or fitting and then welded in place. They also have a bored-out inner diameter that matches the pipe’s outer diameter, allowing for a smooth flow of fluids or gases.

- slip-on flange 2. outside fillet welds 3. inside fillet welds 4. pipe

You can contact us to get the dimension document of the slip-on flange.

Watch the video of product the slip-on flange

Advantages of slip-on flanges relate to lower procurement costs, less required skill for making the weld, lower accuracy requirement for pipe cutting, and no weld preparation requirements for a pipe end weld.

However, if a welding neck flange cannot be used due to space limitations, a slip-on flange may be a suitable alternative.

Whether you are managing a large-scale chemical project or restocking industrial inventory, our flanges meet the most stringent ASME B16.5, EN1092-1, and DIN standards.

Types of Slip-On Flanges and Their Applications

SO flanges are available in two main types, each designed to cater to specific requirements and applications within piping systems:

Standard Slip-On Flanges:

Standard or raised-face SO flanges have a raised face on the sealing surface. They are highly suitable for low-pressure applications where the bolt-tightening force can compress the gasket adequately to prevent leakage.

Lap Joint Slip-On Flanges

Lap joint SO flanges have a flat face with a separate backing flange. They are commonly used in systems requiring frequent dismantling, thermal expansion, or contraction applications.

Technical Specifications

| Category | Technical Details |

| Size Range | 1/2″ to 60″ (DN15 to DN1500) |

| Pressure Ratings | Class 150, 300, 600, 900, 1500; PN6 to PN100 |

| Common Materials | ASTM A105, A350 LF2, ASTM A182 F304/L, F316/L, F51, F11, F22;ASTM A182 |

| Face Types | RF (Raised Face), FF (Flat Face), RTJ (Ring Type Joint) |

| Surface Finish | Anti-rust Oil, Black Paint, Hot Dip Galvanized, Cold Galvanized |

| Compliance | ASME B16.5, B16.47 Series A/B, DIN 2576, EN 1092-1, JIS B2220 |

Key Features of Slip-On Flanges:

Design:

- Slip-on flanges have a flat face and are typically welded to the pipe after being slipped over it. This design allows for easy alignment and installation.

Installation:

- They are easier to install compared to other flange types, as they do not require precise alignment of the pipe ends. The flange can be positioned and then welded in place.

Applications:

- Slip-on flanges are commonly used in low-pressure applications and are suitable for various industries, including oil and gas, water treatment, and chemical processing.

Cost-Effectiveness:

- Generally, slip-on flanges are more cost-effective than other types of flanges, such as weld neck flanges, due to their simpler design and installation process.

Material:

- They can be made from various materials, including carbon steel, stainless steel, and other alloys, depending on the application requirements.

Limitations:

- While slip-on flanges are versatile, they may not be suitable for high-pressure applications due to the potential for leakage at the weld joint.

Slip On Flange vs Weld Neck Flange

- The strength for internal pressure of the Slip-On Flange is two-thirds of Weld Neck Flange.

- Durability life is 1/3 of the WN flange.

- 2 fillet welds are required for the SO flange, one inside and one outside of the flange.

- A space shall be reserved between the end of the pipe and the end of the flange during welding work, to avoid damage to the flange face.

- The slip-on flange has to connect with a pipe first, then connect to a fitting. (Combination of flange+elbow, or flange+tee not available, since the fittings are not in a straight end, it can not slide completely into the flange bore. )

- Slip-on flanges are usually cheaper than Weld-Neck flanges (welding neck flange), which is why many customers prefer to choose them. It is one of the commonly used flanges for low-pressure, medium-temperature piping systems.

On the other hand, since the flange bore is larger than the pipe diameter, it usually requires more welding work than the other flanges. So the durability is not as long as the welding neck flange; all of these factors should be considered before choosing the right flange.

FAQ’s

Q1: How do you perform the welding for a Slip-On flange?

A: A Slip-On flange is welded to the pipe with two fillet welds—one on the outside of the flange and one on the inside near the pipe end.

Q2: Can I use Slip-On flanges for high-temperature service?

A: While they can be used, we recommend consulting our technical team. Slip-On flanges have lower fatigue resistance than Weld Neck flanges in extreme thermal cycling environments.

Q3: What type of anti-corrosion protection do you provide?

A: Depending on the requirement, we offer black bitumous paint, yellow lacquer, or high-performance hot-dip galvanizing for offshore applications.

Trust Rayoung for Industry-Leading Flanges!

Rayoung offers an extensive range of slip-on pipe flanges, catering to various steel material grades such as carbon, stainless, and alloy! We ensure quick availability, allowing you to obtain the required flanges without delays. Our efficient shipping processes also enable swift and reliable delivery, ensuring your project stays on track and meets its deadlines.

For Stockers: We maintain a large inventory of ASTM A105 and SS304/316 standard parts. Leveraging our efficient packaging line, standard orders can be shipped within 72 hours.

For EPC Projects: We support custom orders using special materials (such as Duplex or Alloy Steel) and non-standard sizes. We are familiar with the quality approval processes for large-scale international projects and fully support in-plant testing by third-party certifications.

Contact us to learn more about our products, or request a quote now!

Cooperate with Rayoung, you will enjoy the following benefits.

Rayoung–A leading Butt Weld pipe fittings, flanges and steel pipes supplier& factory in China.

We’re here to help with your industry pipe fittings and flange needs. Rayoung has been in the business of industrial pipe fittings since 1983, and we’re confident we can help you find a solution more quickly, affordably, and with greater expertise than the competition.

We’d love to learn more about your project today!

Pre-sale Service

After-sale Service

Free Sample

Fast Quotation

Cerfifications

Test & Inspection

Customers say:

Talk About Your Needs

We respect your privacy and will not share your personal information with third parties or partners.