Butt Weld Pipe Fittings

We offer an extensive selection of premium butt weld fittings, available in both welded and seamless types to meet diverse industrial needs.

The available materials include Carbon steel, Mild steel, LTCS, and Alloy Steel.

Production Description

Butt Weld Fittings

Butt weld is to connect pipes and fittings ends by the butt welding process. Also known as buttwelded pipe fittings (buttweld fittings). It has ends in beveled or plain. These steel pipe fittings are widely used across various industries, including petrochemical, paper and pulp, water treatment, oil and gas, automobile, and fertilizing applications.

We offer an extensive selection of premium butt weld fittings, available in both welded and seamless types to meet diverse industrial needs. The available materials include Carbon steel, Mild steel, LTCS, and Alloy Steel.

Ranges from usage and functions, butt weld fittings include elbow, tee, reducer, and end cap.

Specification

| Butt Weld Pipe Fitting | ||||

| Product | Butt Weld Elbow | Butt Weld Tee | Butt Weld Pipe Reducer | Steel Pipe End Cap |

| Standard | ASME B16.9, ASME B16.28, GOST 17375-2001, GOST 17376-2001, GOST 17378-2001, GOST 17379-2001, GOST 30753-2001, EN 10253 | |||

| Size | DN 15-DN 2400, 1/2″ – 96″ | |||

| Thickness | SCH 20, STD, SCH 40, SCH60, XS, SCH 80, SCH 160, XXS 2MM-32MM 1.6MM-customized | |||

| Pipe Elbow Ends | Beveling | |||

| Type | LR pipe elbow SR pipe elbow 45 degree pipe elbow 90 degree pipe elbow 60 degree pipe elbow 180 degree pipe elbow Customized degree pipe elbow Equal Tee, Reducing Tee, Barred Tee, Lateral Tee Concentric Reducer, Eccentric Reducer | |||

| Surface Treatment | Black Painting, Transparent Anti-rust Oil, Sand Blast PE/3PE anti-corrosion coating, other customized coatings | |||

| Material | A234-WPB, A420-WPL6, WP304L, WP316L, WP304, WP316, etc.. | |||

| Material in Stock | Carbon steel, Mild steel, LTCS, Alloy Steel | |||

| Package | PP woven bags, pallets, plywood case, etc | |||

| Production Time | 3-5 days for stock goods, 15-30 days for one container, more 10 days for one more container. | |||

| Application | Petroleum, Natural Gas, Water Disposal, Shipbuilding, Nuclear Energy, Chemical Engineering, Deckle, Electric Power | |||

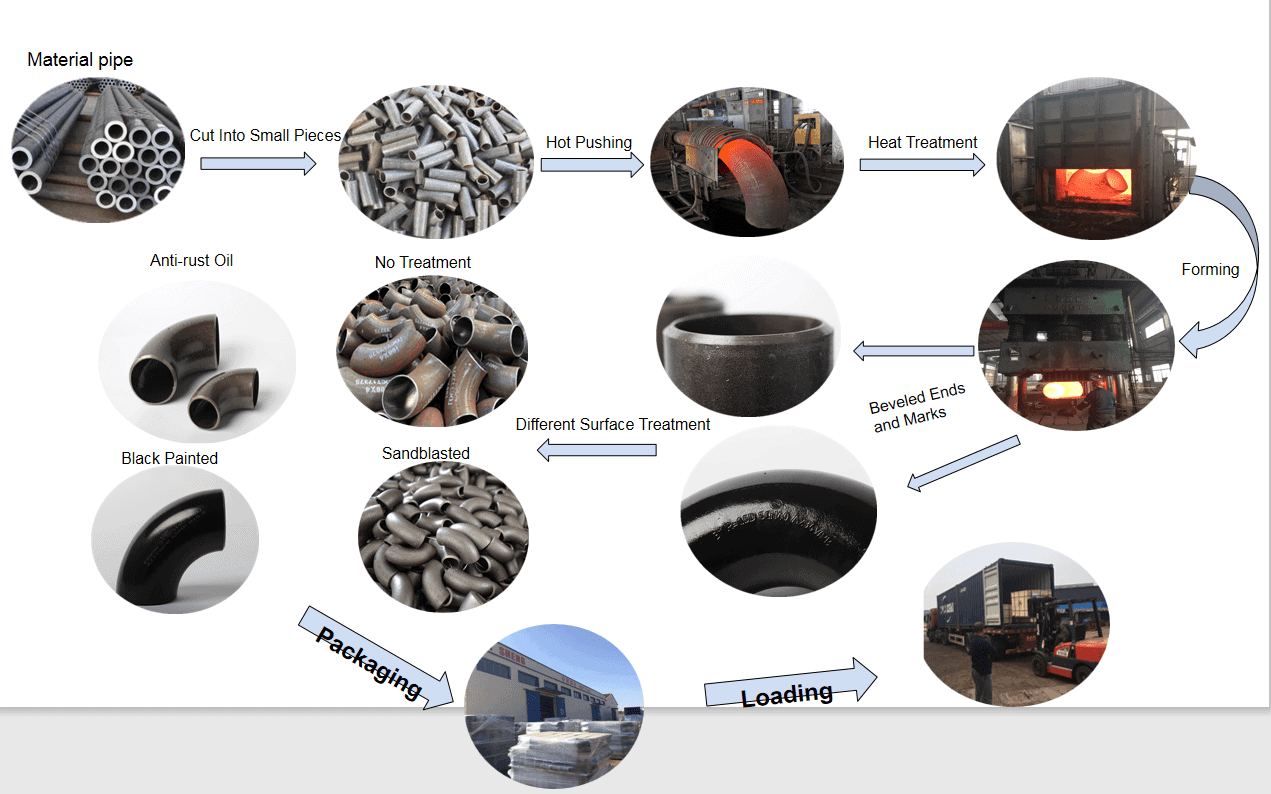

Production process

Our carbon steel butt weld fittings are carefully analyzed according to the strictest quality and safety standards from the selection of raw materials to machining, heat treatment, and packing. Strict quality controls and testing are implemented at every stage of production to ensure only the best products. As a result, our butt weld pipe fittings are popular for their dimensional accuracy, high strength, long service life, leak-proof performance, and corrosion resistance.

Butt weld fittings Applications

Due to Butt weld fittings strength and dependability, butt weld fittings are trusted across a multitude of industries, including:

- Oil and Gas

- Petrochemical Facilities

- Chemical Processing

- Waste Treatment Plants

- Power Generation (including nuclear)

- Paper and Pulp Production

- Gas Processing

- etc.

Principal Advantages

Choosing butt weld fittings offers several considerable benefits for any piping system.

- Strong and Leak-Proof: The welded connection becomes an integral part of the pipe, forming a continuous metal structure that is both exceptionally strong and impervious to leaks.

- Efficient Flow: A smooth inner surface and gradual changes in direction minimize pressure drops and turbulence within the pipe, optimizing flow.

- High-Performance: These fittings are engineered to withstand high pressures and extreme temperatures in demanding environments.

- Long-Term Durability: They provide excellent resistance to corrosion and erosion, making them a lasting and cost-effective choice.

- Space-Saving Design: A welded piping system typically occupies less space than systems using other connection methods.

While the installation process necessitates a skilled welder, the superior strength and long-term reliability of butt weld fittings make them the industry standard for critical applications.

Supply of Buttweld Fittings

Here at Rayoung, we have worked with specialist mills and traders for many years to export the high-quality and reliable buttweld fittings. We have a variety of different fixtures available in different sizes and materials.

All our products are fully tested to international standards, so you can be safe in the knowledge that you are buying high quality products.

Speak to our sales team today.

Cooperate with Rayoung, you will enjoy the following benefits.

Rayoung–A leading Butt Weld pipe fittings, flanges and steel pipes supplier& factory in China.

We’re here to help with your industry pipe fittings and flange needs. Rayoung has been in the business of industrial pipe fittings since 1983, and we’re confident we can help you find a solution more quickly, affordably, and with greater expertise than the competition.

We’d love to learn more about your project today!

Pre-sale Service

After-sale Service

Free Sample

Fast Quotation

Cerfifications

Test & Inspection

Customers say:

Talk About Your Needs

We respect your privacy and will not share your personal information with third parties or partners.