LSAW Steel Pipe for Oil and Gas Pipelines

Standards:ASTM A53, ASTM A106、API 5L、ASTM A519, ASTM A213/A213M

Length: 6m – 18m (Custom lengths available upon request)

Ends: Square Ends/Plain Ends (straight cut, saw cut, torch cut), Beveled/Threaded Ends

Application: Used for oil/gas/water Transmission, Engineering/Offshore projects, and Structural Support in Industrial Construction

Production Description

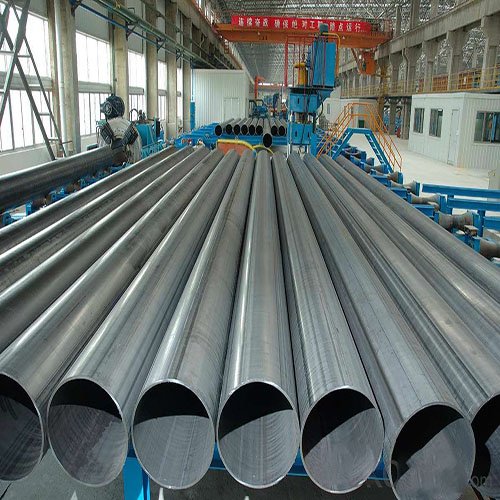

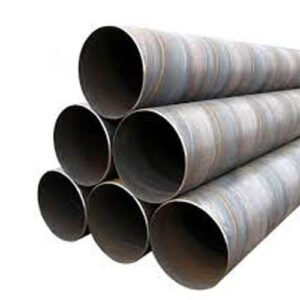

LSAW (Longitudinal Submerged Arc Welded) steel pipes are the preferred choice for long-distance oil and gas pipelines, offshore piling, and high-pressure fluid transmission. Utilizing the JCOE or UOE production process, our LSAW pipes offer superior structural integrity and dimensional precision for demanding engineering environments.

What is LSAW Steel Pipe?

LSAW steel pipe is manufactured by forming heavy steel plates into a cylindrical shape and welding the longitudinal seam using submerged arc technology. Unlike ERW pipes, LSAW is specifically designed for large diameters (16″ to 60″+) and heavy wall thicknesses, making it indispensable for critical infrastructure where safety and pressure resistance are non-negotiable

Technical Specifications & Standards

We supply LSAW pipes that strictly adhere to international benchmarks. Whether you are a stockist looking for API 5L inventory or a contractor needing specific ASTM grades, our production line covers:

| Feature | Specification Details |

| Outer Diameter (OD) | 406mm – 1524mm (16″ – 60″) |

| Wall Thickness (WT) | 6mm – 50mm (Sch20 – SchXXS) |

| Length | 6m – 12.5m (Single/Double Random Length or Custom) |

| Manufacturing Standards | API 5L (PSL1 & PSL2), ASTM A671, ASTM A672, EN 10219, ASTM A252 |

| Material Grades | Gr.B, X42, X52, X60, X65, X70, X80, Grade 2/3 |

| Weld Type | Longitudinal Submerged Arc Welding (Single or Double Seam) |

| Surface Treatment | Bare, Black Painting, Anti-rust Oil, 3PE/FBE Coating, Galvanized |

Straight Seam Submerged Arc Welded Steel Pipe

UOE SAWL PIPES

Outside Diameter:Φ508mm- 1118mm (20″- 44″)

Wall Thickness: 6.0-25.4mm 1/4″-1″

Quality Standards: API、DNV、ISO、DEP、EN、ASTM、DIN、BS、JIS、GB、CSA

Length: 9-12.3m (30′- 40′)

Grades: API 5L A-X90,GB/T9711 L190-L625

JCOE SAWL PIPES

Outside Diameter:Φ406mm- 1626mm (16″ – 64″ )

Wall Thickness:6.0- 75mm (1/4″ – 3″ )

Quality Standards:API、DNV、ISO、DEP、EN、ASTM、DIN、BS、JIS、GB、CSA

Length:3-12.5m ( 10′- 41′ )

Grades:API 5L A-X100, GB/T9711 L190-L690

Key Industry Applications

Our LSAW piping solutions are engineered for high-stress applications across various sectors:

- Oil & Gas Midstream: High-pressure onshore and offshore transmission pipelines for crude oil, natural gas, and slurry.

- Structural & Piling: Heavy-duty foundation piles for bridges, skyscrapers, and marine wharf construction (ASTM A252 compliant).

- Water Conservancy: Large-scale water supply systems and industrial cooling water circuits.

- Mechanical Engineering: Used in the fabrication of offshore platforms and high-temperature pressure vessels.

RAYOUNG – The Steel Pipe Experts for Oil and Petroleum Industry

We’re HEBEI RAYOUNG PIPELINE TECHNOLOGY CO. LTD., and we build something really important — steel pipelines. These are big, strong tubes made of steel that help carry oil and gas from one place to another.

You might not see them every day, but the pipeline for oil and gas is deep underground or under the sea. Without them, your car, home heater, or even electricity might not work the way it should. We make and supply super-strong steel pipes. Our petroleum pipelines don’t break easily. They can handle heat, pressure, and bad weather. That’s why oil and gas companies love working with us. We also check every oil pipeline carefully. Safety of oil field pipeline is our top rule.

Why Our Pipelines Are Special

Not all steel pipes are the same. Some are good. Some petroleum pipelines are better. Ours are the best. Why?

- Because we use the strongest steel for our pipeline for oil and gas.

- Because we test each oil field pipeline before we send it.

- Because we care about the job and the people who do it.

Even the smallest mistake in an oil pipeline can be dangerous. So, we take our work seriously.

Who Do We Work With?

We work with big oil and gas companies. They trust HEBEI RAYOUNG PIPELINE TECHNOLOGY CO. LTD. because we never let them down. We deliver on time. We deliver with care. We also work with engineers, builders, and smart teams who install our pipelines safely.

Cooperate with Rayoung, you will enjoy the following benefits.

Rayoung–A leading Butt Weld pipe fittings, flanges and steel pipes supplier& factory in China.

We’re here to help with your industry pipe fittings and flange needs. Rayoung has been in the business of industrial pipe fittings since 1983, and we’re confident we can help you find a solution more quickly, affordably, and with greater expertise than the competition.

We’d love to learn more about your project today!

Pre-sale Service

After-sale Service

Free Sample

Fast Quotation

Cerfifications

Test & Inspection

Customers say:

Talk About Your Needs

We respect your privacy and will not share your personal information with third parties or partners.