FBE Coated Steel Pipe

Pipe Type: FBE (Fusion Bond Epoxy) Coated Pipe, Epoxy Coated Carbon Steel Pipe, Single-layer Anti-corrosion Epoxy Powder Pipe, Double-layer FBE Coating Pipes

Application: Used for natural gas, petroleum, water & sewage, and pipe systems. In such cases, they should exhibit high resistance to corrosion from chemicals, moisture, and harmful environments.

Pipe Type: Submerged Arc Welded (LSAW/SSAW pipe), Electric Resistance Welded(ERW pipe)

End: Plain End/Bevelled End, Burr Removed

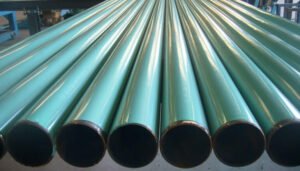

Surface: One Layer / Double Layer FBE anti-corrosive coating powder.

Production Description

FBE coated steel pipe is a Fusion Bonded Epoxy-coated steel pipe. It is an externally applied heat-resistant resin for pipes. With a form of dry powder at a thickness of 400-600 microns onto the heated surface of the pipe. Once the FBE is coated on the pipe surface, the FBE film provides an extremely hard surface with great adhesion to the pipe surface.

The FBE layer is in an even form and has good resistance to the chemical reaction.

Standard: AWWA C213、API RP 5L7、CAN/CSA Z245.20、ISO 21809-2、API RP 5L9、AS 3862,DIN

FBE Coating Steel Pipe Advantages:

- Convenient for spraying, no pollution, excellent resistance to high temperatures (-40°C to 85°C);

- High strength and anti-bending performances;

- Strong adhesion, good integrity, anti-soil stress, and wear.

- FBE-coated steel pipe is usually buried in soil and underwater between -40~85°C temperatures.

Epoxy coatings offer a robust and visually appealing solution for protecting steel pipes, enhancing both their durability and lifespan.

These coatings are available in a vibrant spectrum of colors and are suitable for various types of steel, making them a versatile choice for numerous applications.

Epoxy coatings for steel pipes are not just about protection; they also add aesthetic value. Popular color choices include shades of blue, red, green, yellow, and orange. For a more premium look, metallic options like silver and gold are also available.

Beyond the visual appeal, it is crucial to select a high-quality epoxy coating capable of withstanding harsh environmental conditions to ensure long-term functionality and appearance.

Applications

The application of epoxy-coated steel pipes spans across various industries due to their strength and corrosion resistance:

1. Pipeline Transportation: A protective layer of epoxy is essential for the safe and efficient transport of petroleum, gas, and other liquids, as it prevents rust, corrosion, and damage from chemicals.

2. Water Distribution: In systems for drinking, irrigation, and industrial water, epoxy coatings help maintain water quality by preventing corrosion and inhibiting the growth of harmful bacteria.

3. Construction: The strength and durability of epoxy-coated steel pipes make them ideal for use in demanding construction projects like bridges, tunnels, and buildings, where they protect structural weakening from rust and corrosion.

4. Oil and Gas Exploration: These coatings are widely used to protect pipes from corrosion and damage caused by harsh chemicals and abrasive materials, which in turn extends the pipeline’s life and reduces maintenance expenses.

5. Other Industries: The versatility of epoxy coatings also extends to wastewater treatment plants, the chemical processing industry, the food and beverage industry, and even residential plumbing.

In such cases, they should have high resistance to corrosion from chemicals, moisture, a harmful environments, etc

Suitable Steel Types for Epoxy Coating

Several types of steel pipes can benefit from an epoxy coating:

Carbon Steel: Known for its strength and durability, carbon steel is a common choice for epoxy coating, particularly in construction and manufacturing, due to its high corrosion resistance.

Stainless Steel: This type of steel is often favored in the food and beverage industry, where hygiene is paramount.

Alloy Steel: For pipes exposed to harsh chemical environments, alloy steel is an excellent option as it offers high resistance to both corrosion and wear.

Cooperate with Rayoung, you will enjoy the following benefits.

Rayoung–A leading Butt Weld pipe fittings, flanges and steel pipes supplier& factory in China.

We’re here to help with your industry pipe fittings and flange needs. Rayoung has been in the business of industrial pipe fittings since 1983, and we’re confident we can help you find a solution more quickly, affordably, and with greater expertise than the competition.

We’d love to learn more about your project today!

Pre-sale Service

After-sale Service

Free Sample

Fast Quotation

Cerfifications

Test & Inspection

Customers say:

Talk About Your Needs

We respect your privacy and will not share your personal information with third parties or partners.