ASME Flanges

ASME B16.5 flanges are specifically designed for pipe sizes ranging from ½” to 24″. They are available in pressure classes 150, 300, 400, 600, 900, 1500, and 2500.

ASME B16.47 flanges cover larger-diameter pipe systems, 26″ through 60″, with pressure classes such as 75, 150, 300, 400, 600, and 900.

Production Description

As a dedicated industrial forging facility, we specialize in the engineering and bulk supply of ASME Steel Flanges for global traders, stockists, and large-scale infrastructure projects. Our production line focuses on delivering high-precision components that meet the rigorous demands of high-pressure and high-temperature environments.

We maintain a massive inventory of Carbon Steel (ASTM A105) and Stainless Steel (304L/316L) flanges, ensuring that your procurement cycle remains uninterrupted and your supply chain stays resilient.

Comprehensive Standards Compliance: ASME B16.5 & B16.47

Our manufacturing process adheres strictly to American Society of Mechanical Engineers (ASME) protocols, providing full traceability and dimensional accuracy.

1. ASME B16.5 Flanges (1/2″ to 24″)

For standard piping systems, we offer a complete range of B16.5 forged steel flanges.

Pressure Classes: 150, 300, 400, 600, 900, 1500, and 2500.

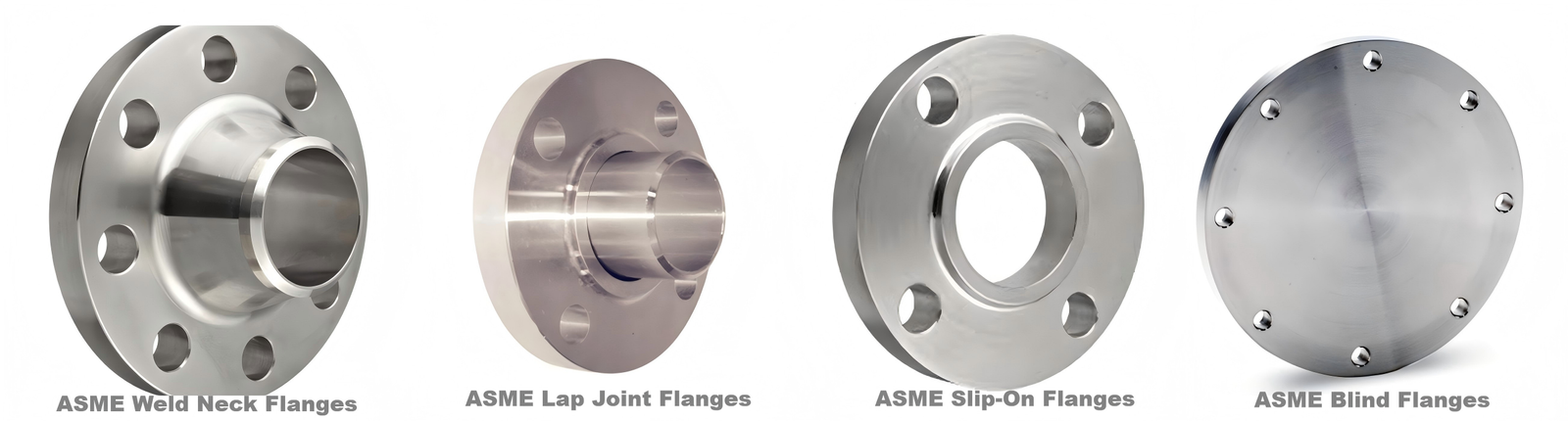

Types Available: Slip-on (SO), Blind (BL), Weld Neck (WN), Threaded (TH), Socket Weld (SW), and Lap Joint (LJ).

Face Designs: Raised Face (RF) flange and Flat Face (FF) flange.

2. ASME B16.47 Large Diameter Flanges (26″ to 60″)

Designed for heavy-duty systems, our large-diameter flanges handle high volumes with ease.

Series A (MSS SP-44): Ideal for heavy-duty applications, specifically covering Blind and Weld Neck styles.

Series B (API 605): Optimized for compact, high-pressure environments, offering a more lightweight alternative for specific piping configurations.

Pressure Classes: 75, 150, 300, 400, 600, and 900.

Material & Technical Specifications

To support the diverse needs of ToB traders and stockists, we provide a versatile material portfolio:

Carbon Steel: ASTM A105 (Standard for high-temp service).

Stainless Steel: ASTM A182 F304/304L, F316/316L (Superior corrosion resistance).

Surface Finishings: Anti-rust oil, Black paint, Yellow transparent, or Galvanized (Hot-dip/Cold).

Custom Solutions: Beyond standard dimensions, our facility offers custom forging based on unique blueprints and material grades for niche industrial uses.

ASME Steel Flange Types

Industrial Applications

Our ASME-standard steel flanges are currently deployed in mission-critical sectors worldwide, including:

- Oil & Gas: Upstream drilling and downstream refineries.

- Petrochemical: Chemical processing and heat exchanger systems.

- Power Generation: Nuclear and thermal power facilities.

- Infrastructure: Municipal water treatment and large-scale manufacturing plants.

Why Partner With Our Factory?

- Direct Factory Pricing: Cut out the middleman and maximize your profit margins.

- Bulk Stock Availability: We maintain ready-to-ship stock for Class 150 and 300 Slip-on and Blind flanges.

- Strict QC & Documentation: Every shipment is accompanied by a Material Test Certificate (MTC) and complies with ASTM/ASME standards.

- Flexible Logistics: Strategic shipping solutions to ensure your bulk orders arrive on time, anywhere in the world.

ASME Flanges FAQ’s

Q1: What is the practical difference between ANSI and ASME flanges?

While “ANSI Flanges” is a common industry term, it refers to standards developed by ASME. Today, ASME B16.5 is the active standard for sizes up to 24″, while ASME B16.47 governs 26″ to 60″. Buying from us ensures your products meet the latest ASME revisions required by modern engineering inspectors.

Q2: How do I choose between Series A and Series B for large diameter flanges?

Series A flanges are generally thicker, heavier, and can withstand more external loading than Series B. Series B is often preferred for replacement parts in older systems or where space and weight are critical factors. We can provide both to match your specific project requirements.

Q3: Does your factory provide custom coatings?

Yes. We offer various metal finishing options, including specialized coatings to prevent corrosion during long-term sea freight or storage in humid stockist warehouses.

Q4. What are the pressure ratings for ASME B16.5?

ASME B16.5 includes seven standard pressure classes: 150, 300, 400, 600, 900, 1500, and 2500. These ratings define the maximum allowable pressure a flange can withstand, depending on material type, temperature, and application.

Q5. Where is ASME B16.5 used?

ASME B16.5 is used in industries such as oil and gas, chemical processing, power generation, and water treatment, where flanged piping systems are required.

Cooperate with Rayoung, you will enjoy the following benefits.

Rayoung–A leading Butt Weld pipe fittings, flanges and steel pipes supplier& factory in China.

We’re here to help with your industry pipe fittings and flange needs. Rayoung has been in the business of industrial pipe fittings since 1983, and we’re confident we can help you find a solution more quickly, affordably, and with greater expertise than the competition.

We’d love to learn more about your project today!

Pre-sale Service

After-sale Service

Free Sample

Fast Quotation

Cerfifications

Test & Inspection

Customers say:

Talk About Your Needs

We respect your privacy and will not share your personal information with third parties or partners.