Industry Forged Flanges-ASME/ANSI Standard and Non-standard

The forged steel flanges are suitable for the connection of steel pipes conveying mediums such as steam, oil, air, and water. They are widely used in the oil gas Chemical industry and Shipbuilding. The forged flanges mainly include Welding Neck, Blind, Slip-on, Lap-Joint, Socket ,Blind and Plate flange type.

Production Description

Forged flange is a plate-type device, usually in circular appearance, which could be attached to the ends of pipes, fittings, valves, or other objects to facilitate assembly and disassembly of the piping system. It offers impressive mechanical performance as a connecting part.

Forged steel flange has higher precision and performance than the cast flange and is widely used in different industries for connecting equipment or pipelines, especially for high temperature and high pressure environments.

Standards

Standard Forged Flanges (Weld-neck, Slip-on, Socket-weld, and Blind flange) are manufactured by Rayoung to different specifications like ASME, ANSI standards. Our Forged Flanges cover a full range of pressure ratings of these specifications.

Manufacturing Standards Referred

- ASME B16.5: Dimension standard for steel pipe flanges and flanged fittings

- ASME B16.47: Large diameter steel flanges NPS 26 to NPS 60

- MSS-SP44: For steel pipeline flanges

- API 605: For large diameter carbon steel flanges

Types of Forged Flanges

Industrial welded forged flanges come in many different types. Each species meets its special requirements. For example, long weld neck flanges are attached to the necks of the pipes.

There is also have weld neck flange

Forged Flange Pressure Ratings

- Class 150 lb

- Class 300 lb

- Class 600 lb

- Class 900 lb

- Class 1500 lb

- Class 2500 lb

Specification

| Industrial Steel Forged Flange | |||||||||||

| Standard | ASME/ANSI B 16.5 | ASME B 16.47 | ASME B 16.48 | GOST 12821 | GOST 12820 | GOST 33259 | EN 1092 | DIN | JIS | SABS/SANS 1123 | BS 4504 |

| Size | 1/2″-24″ | 26″-60″ | 1/2″-24″ | DN10-DN1200 | DN10-DN1200 | DN10-DN2400 | DN10-DN2000 | DN10-DN2000 | DN10-DN1500 | DN10-DN600 | DN10-DN4000 |

| Pressure | Class 150 300, 400 600, 900 and 2500 | Class 75 150, 300 400, 600 and 900 | Class 150 300, 400 600, 900 and 2500 | PN6, PN10 PN16, PN25 PN40, etc | PN6, PN10, PN16, PN25 | PN6, PN10, PN16, PN25, PN40, etc | PN6, PN10 PN16, PN25 PN40, etc | PN6, PN10, PN16, PN25, PN40, etc | 5KG, 10KG 16KG, 20KG 30KG, 40KG etc | 1600/3 1600/4 Table D Table E | PN 2.5 PN6, PN10 PN16, PN25 PN40, etc |

| Material | Carbon steel: Steel 20#, A105, A105N, Q235, 16Mn, Q345, etc Alloy steel: ASTM A182 F11, F22, LF2 Stainless steel: 304/L, 316/316L | ||||||||||

| Flange Type | Weld Neck Flange, Slip-on Flange, Socket Welding Flange, Plate Flange, Blind Flange, Lap Joint Flange, Threaded Flange, Orifice Flange, Spectacle Flange, Stub End, Weld Neck Collar, Welding-on Collar | ||||||||||

| Sealing Face | Raised Face (RF), Flat Face(FF), Ring Joint Face(RTJ), Male Face-Female Face(SMF), Tongue Face & Groove Face | ||||||||||

| Surface Treatment | Anti-rust Oil, H.D.G., Black Painting, Yellow Painting, Red Painting, Etc | ||||||||||

| Technique | Cutting – Heat Treatment – Forging – Machining – Drilling – Painting | ||||||||||

| Certificates | ISO 9001, CE, GOST-R, CCS, EN 10204/3.1B, MTC, Radiography Test Report, Ultrasound Test Report, SGS and other third party Inspection Reports | ||||||||||

| Package | Pallets, Plywood Case, etc | ||||||||||

| Application | Petroleum, Natural Gas, Water Disposal, Shipbuilding, Nuclear Energy, Chemical Engineering, Deckle, Electric Power | ||||||||||

Surface Treatment

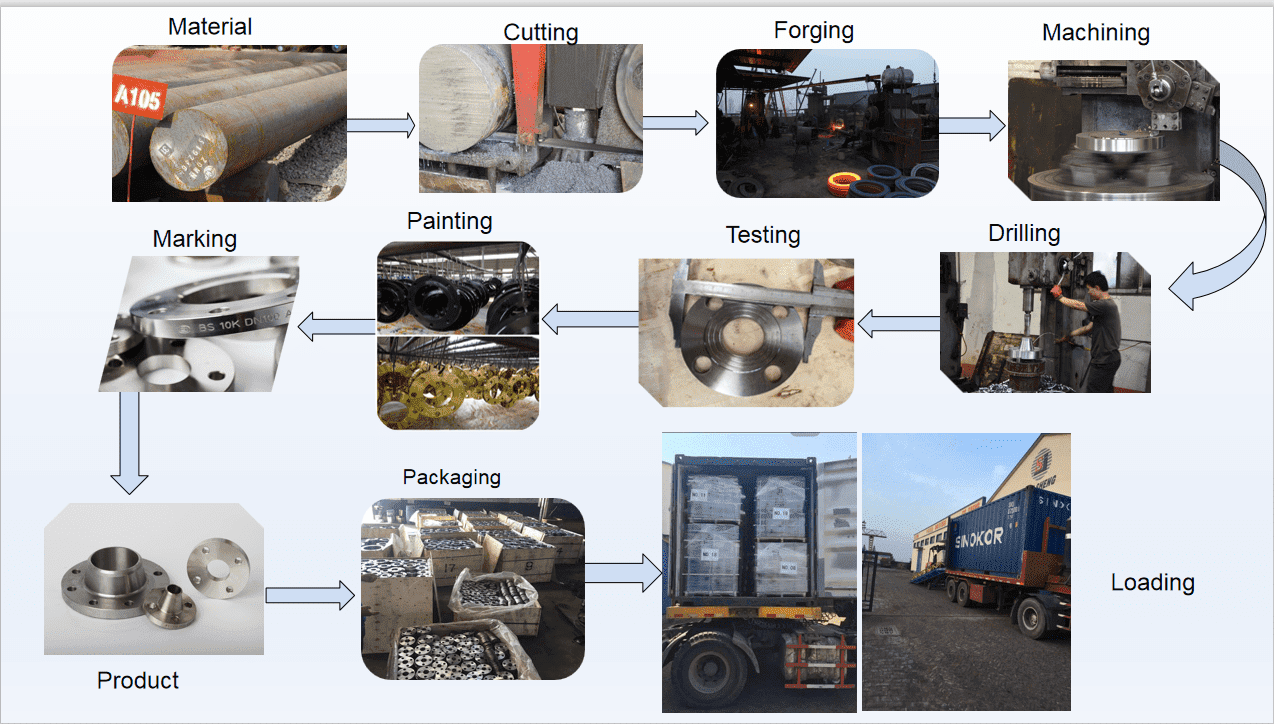

Production process

Industrial Forged Flanges Key Applications:

1. Oil and Gas Industry:

Forged flanges are essential in oil and gas extraction, transportation, and refining processes. Their ability to withstand high pressure and temperature makes them suitable for pipelines, refineries, and offshore platforms.

2. Petrochemical and Chemical Plants:

These welded forged flanges are used to connect pipes and equipment handling corrosive chemicals in petrochemical and chemical processing plants. Materials like stainless steel and specialized alloys are often employed for their corrosion resistance.

3. Power Generation:

Forged flanges play a vital role in power plants, including nuclear, thermal, and hydroelectric facilities. They connect piping systems transporting steam, water, and other fluids under high pressure and temperature.

4. Water Treatment and Distribution:

They are used in water and wastewater treatment plants to ensure reliable fluid transport in pipelines and systems.

5. Shipbuilding and Marine Applications:

In marine environments, forged flanges provide durable and corrosion-resistant connections in pipelines on ships and submarines.

6. Food and Pharmaceutical Industries:

Where hygiene and corrosion resistance are critical, forged flanges, particularly those made of stainless steel, are used in processing equipment for handling sensitive liquids and gases.

7. HVAC Systems:

Forged flanges are also used in heating, ventilation, and air conditioning (HVAC) systems for reliable connections in piping networks.

8. Structural Applications:

In some cases, forged flanges are used in structural frameworks for added support and stability.

Why order forged Flanges in Bulk from RAYOUNG?

We make thousands of ASME B16.5 flange units every month. When you buy in bulk, we give you better prices.

That means you save money. And saving money is always good, right? Also, you don’t have to worry about quality. We check every single piece before it leaves our factory.

Our flanges are super tough. The ASME B16.5 flange can handle pressure, heat, cold, and heavy use. Whether it’s for a building, a factory, or a ship, these flanges do the job right. They don’t rust. They don’t crack. They don’t fail.

Cooperate with Rayoung, you will enjoy the following benefits.

Rayoung–A leading Butt Weld pipe fittings, flanges and steel pipes supplier& factory in China.

We’re here to help with your industry pipe fittings and flange needs. Rayoung has been in the business of industrial pipe fittings since 1983, and we’re confident we can help you find a solution more quickly, affordably, and with greater expertise than the competition.

We’d love to learn more about your project today!

Pre-sale Service

After-sale Service

Free Sample

Fast Quotation

Cerfifications

Test & Inspection

Customers say:

Talk About Your Needs

We respect your privacy and will not share your personal information with third parties or partners.