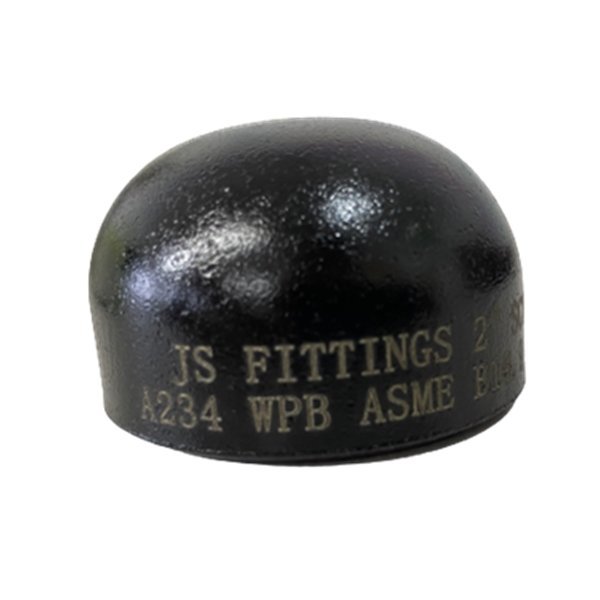

Buttweld Cap ASME ANSI B16.9

Standard: ASTM A234, MSS SP-75, ASTM A403

Manufacturing Standard: ASME ANSI B16.9, DIN2615, JIS B2312

Size Range: 1/2”, 1”, 2”, 3”, 4”, 6”, 8”, 10”, 12”, 16”, 20” to 48”. (DN15-DN1200)

Thickness: SCH 10, SCH 40, SCH 80

Material: Carbon Steel, Stainless Steel, Alloy Steel

Surface Coatings: Black Painted, Varnished, Epoxy Coated, Galvanized

Production Description

Butt Weld Steel Pipe End Cap Prevents Fluid Leakage

Carbon steel butt weld cap is a commonly used pipe fitting, also known as a pipe cap or end cap. Its main function is to seal the end of the pipe to prevent fluid leakage and external substances from entering the pipe, and ensure the safe operation of the pipeline system. (You can also use a blind plate to close the pipeline; differently, the blind plate is detachable and the welded steel cap is not removable.)

It is usually circular and matches the outer diameter of the pipe. It is connected to the end of the pipe by welding. Due to the strong welding connection, it can withstand high pressure and temperature, and maintain reliable sealing performance.

Click here to know the buttweld caps applications.

We are a butt weld caps manufacturer in China, supplying all schedules in various materials, including carbon steel, stainless steel, and alloy steel. Rayoung produces buttweld pipe caps in ASME, DIN, JIS, and other required standards. And it has excellent corrosion resistance and can resist corrosion media such as oxidation, acidity, alkalinity, and salt solutions.

Product Name | Buttweld pipe cap |

Material | carbon steel A234 WPB, stainless steel, alloy steel and so on |

OD | 1/2″–72″ |

Standard | DIN GB ISO JIS BA ANSI and so on |

WT | Sch10–XXS |

Color | polishing color, black and so on |

Coating | Black paint, oil paint, or according to your requirement |

Application | petroleum, chemical industry, medicine, electric power, astronautics, war industry, fire prevention, metallurgy, shipbuilding, fuel gas, nuclear electricity, urban construction, hot-water heat, and environmental protection, etc. |

Material Grades:

Carbon Steel Butt Weld Cap: ASTM A234 WPB, A420 WPL3,WPL6, WPL9,WPHY42, WHPY52, WPHY60, WHPY65, WPHY70.

Stainless Steel Pipe Cap: ASTM A403 WP304/304L, 316/316L, 321, 310S, 317,347

Alloy Steel BW Pipe Cap: ASTM A234 WP1, WP5, WP9, WP11, WP12, WP22, WP91

Butt weld caps can effectively prevent the leakage of media in the pipeline to the external environment. Especially when transporting liquids or gases in the pipeline, the sealing performance of butt weld caps must ensure that the media will not leak accidentally, thereby guaranteeing the safety of the system. It can also effectively prevent external substances such as dust, impurities, and moisture from entering the pipeline, thereby avoiding contamination of the media inside the pipeline. This is very important for applications that require maintaining the purity of the media or avoiding external influences.

Contact Us for an Immediate Offer!

RAYOUNG is proud to be recognized among the most reliable pipe fitting companies and a professional pipe fittings manufacturer. Our team works alongside builders, engineers, and project managers to deliver tailored solutions for each demand.

Our manufacturing role as pipe fitting makers focuses on meeting expectations beyond client requirements through customized orders and expedited delivery services.

We can provide engineering trading and stockists with a stable supply of goods.

Cooperate with Rayoung, you will enjoy the following benefits.

Rayoung–A leading Butt Weld pipe fittings, flanges and steel pipes supplier& factory in China.

We’re here to help with your industry pipe fittings and flange needs. Rayoung has been in the business of industrial pipe fittings since 1983, and we’re confident we can help you find a solution more quickly, affordably, and with greater expertise than the competition.

We’d love to learn more about your project today!

Pre-sale Service

After-sale Service

Free Sample

Fast Quotation

Cerfifications

Test & Inspection

Customers say:

Talk About Your Needs

We respect your privacy and will not share your personal information with third parties or partners.