In industrial projects involving piping systems, the selection of the right flange holds paramount importance.

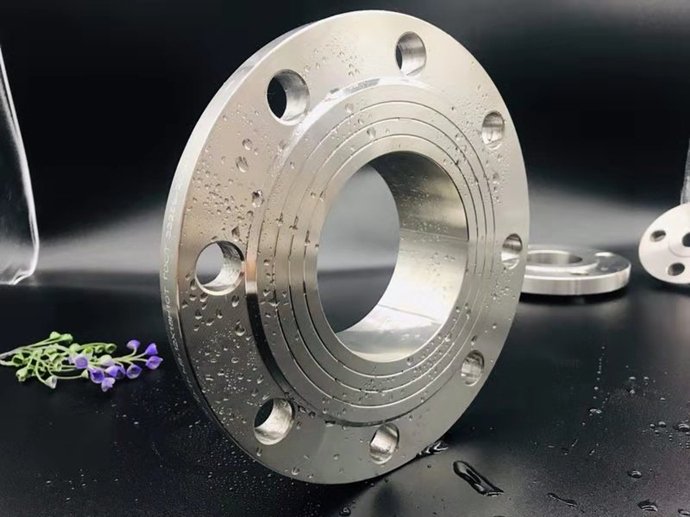

Flanges are used to connect valves, pipes, pumps, and other equipment to make a pipework system. Typically, flanges are welded or threaded, and two flanges are connected by bolting them with gaskets to provide a seal that provides easy access to the piping system. These Flanges are available in various types such as slip-on flanges, weld neck flanges, blind flanges, and socket weld flanges etc.

How to Choose the Right Flange for Your Pipeline?

Projects in the oil and gas sector are unique, necessitating specific pipe flanges to perform the job.

The most common types of flanges used in the petrochemical industry are:

lap joint flange, Blind flange, Socket weld flange, Welding neck flange, Slip-on flange.

Other special flanges commonly used in the oil and gas industry include:

Long weld neck flanges, Orifice flange, Expander flange, Reducing flange, Nipoflange.

1. Defining the facing of your flanges is one of the first steps to ordering the industrial pipe flanges.

Pipe flanges come in different face types, including flat face, raised face, and ring-type joint.

The flat face flange is suitable for low-pressure applications, while the raised face flange is suitable for high-pressure applications.

The ring-type joint flange is used in extremely high-pressure applications.

2. Pick Out the Correct Pressure Class

The pressure class of a flange standard determines its dimensions.

Four factors that influence the pressure limits of the flanges within the oil and gas industry include:

* Dimensions, thickness, number, and size of bolts

* Internal and external temperatures

* Material used

* Flange sizes

You can consult your fitting distributor to determine the right flange pressure class for your project.

3. Choose the Right Material

The choice of material is critical for ensuring a flange’s durability and performance.A general rule is to match the flange material to the pipe material to prevent issues like galvanic corrosion. The fluid being transported, operating conditions, and environmental factors will dictate the best material.

Common Flange Materials:

Forged Carbon Steel: The most common material used in the industry due to its strength and reliability.

Stainless Steel: Preferred for corrosive environments and offers excellent resistance to high temperatures.

Alloy Steel: Contains other elements like chrome-moly to provide enhanced strength and durability for specialized, high-stress applications.

4. Standards and Certifications

When selecting pipe flanges, it’s important to consider if they meet the necessary standards and certifications for the intended application. These may include ASME B16.5, ASME B16.47, and API 6A. Flanges may also require specific certifications, such as ASTM or ASNT. Meeting the required standards and certifications is crucial for ensuring the safety and reliability of the pipeline system.

Oil and gas plants are large, complex environments with thousands of miles of interconnected piping. There’s an endless list of factors to consider when you choose flanges for the Industrial Pipeline system. However, the given above are a few specific or crucial ones you must not skip out.

Choosing the right flange is pivotal for ensuring seamless pipeline operation and longevity. By considering factors such as pipe material, pressure and temperature requirements, flange specifications, and ease of maintenance, you can make informed decisions to optimize your pipeline’s performance.

As a flanges supplier, We have over 100 years of experience in the pipe flange industry. Further, we specialize in producing and supplying oil gas industry pipe flanges, with a focus on meeting the highest industry standards and certifications.

At RAYOUNG, we are committed to providing our customers with the highest quality products and services! Contact us to learn more, or request a quote to partner with us today.

+86-18003119682

info@hb-steel.com