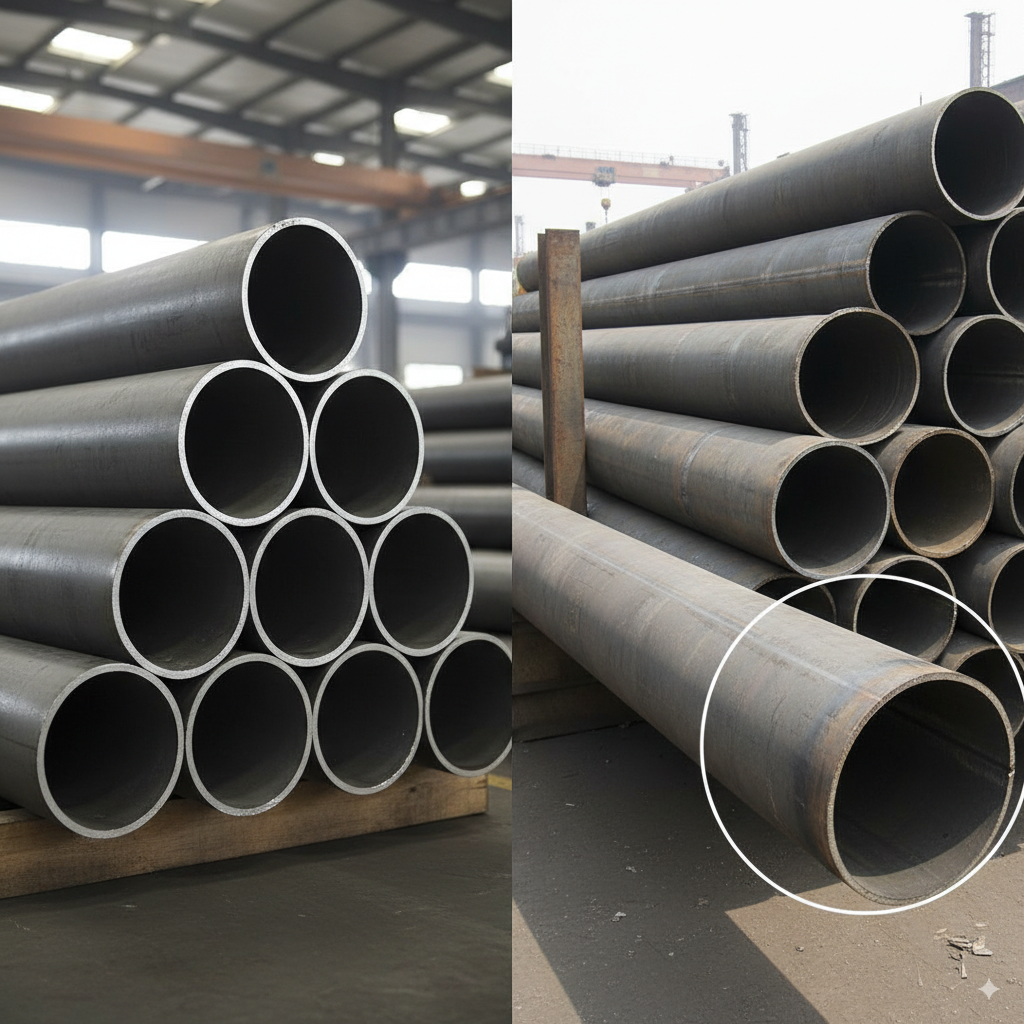

What is Carbon Steel Pipe?

Carbon steel pipes, often referred to as CS pipes, are crafted from steel ingots or solid round bars, meticulously processed through hot rolling, cold rolling, or cold drawing into capillary tubes. This manufacturing rigor imbues them with exceptional strength and formidable pressure resistance, making them a cornerstone in demanding sectors. Their resilience is why they are vital in infrastructure development, maritime applications, sophisticated stills, oil, gas, chemical, and fertilizer production, forming the very arteries of modern industry.

We offer a comprehensive range of carbon steel pipes, each tailored to specific application needs:

Seamless Carbon Steel Pipes: Produced through hot rolling or cold drawing, these pipes are celebrated for their superior strength, impeccable tightness, and consistent wall thickness, ideal for high-pressure and critical applications.

Welded Carbon Steel Pipes: Formed by expertly rolling steel plates or strips into a cylindrical shape, with seams joined via advanced resistance welding (ERW) or submerged arc welding (SAW). These offer cost-effectiveness without compromising structural integrity for a wide array of uses.

Carbon steel pipe Applications:

The adaptability of carbon steel pipes ensures their extensive use across a multitude of industries, valued for their durability, inherent corrosion resistance, and ease of fabrication.

- Oil and Natural Gas: As the conduits for the world’s energy, carbon steel pipes provide unparalleled strength, reliability, and corrosion resistance for pipelines, guaranteeing the safe and efficient transmission of vital oil and gas resources.

- Construction & Structural Engineering: Integral to the stability of our built environment, they form the structural backbone of bridges, high-rise buildings, roads, and tunnels, bearing significant loads with unwavering durability.

- Automotive Manufacturing: Within vehicle design, these steel pipes are crucial for exhaust systems, frames, and chassis components, delivering the wear resistance and strength essential for peak performance.

- Mechanical Engineering: They are indispensable in conveying systems, pressure vessels, and hydraulic components, providing the robustness and reliability required in demanding mechanical environments.

- Chemical Industry: Essential for conveying systems, reactors, and storage tanks, our pipes offer the necessary corrosion resistance and high-temperature endurance critical for complex chemical processes.

Carbon Steel Pipe Standards and Grades (Seamless and Welded):

Rayoung’s carbon steel pipes are manufactured to the most stringent international standards, ensuring compatibility and performance wherever they are deployed. Our extensive products include:

ASTM A106 Gr. B: Seamless steel pipe for high-temperature service.

ASTM A53 Gr. A, B: Seamless, ERW welded, and zinc-coated (hot-dipped galvanized) steel pipe for general purpose.

ASTM A179 Gr. C: Seamless cold-drawn low-carbon steel for heat-exchanger and condenser tubes.

ASTM A192: Seamless carbon steel boiler tubes for high-pressure service.

ASTM A252: Welded and seamless steel pipe piles.

ASTM A333 GR. 1 to 6: Seamless and welded steel pipe for low-temperature service with required notch toughness.

ASTM A134 & A135: For electric resistance welded (ERW) steel pipes.

API 5L (ISO 3183): Covering Gr. A, B, X42 to X80 in seamless and welded (LSAW, SSAW, ERW) formats, specifically for petroleum and natural gas pipeline transportation systems.

DIN 2440 & DIN 2444: Seamless and welded steel pipes, including hot-dip galvanized options for medium-weight tubes.

CSZ Z245: Seamless and ERW welded pipe (excluding low-frequency electric welded), and SAW steel pipe for oil and gas pipeline systems.

Should your project demand unique specifications, our team is equipped to source and provide materials conforming to additional standards.

Coating types for carbon steel pipe against corrosion environments:

To enhance the longevity and performance of our steel pipes in corrosive and abrasive environments, Rayoung offers a range of advanced coating systems:

3PE Coated: A robust 3-layer polyethylene coating providing superior protection.

FBE Coated: Fusion Bonded Epoxy coating, ideal for strong adhesion and chemical resistance.

Zinc Coated: Hot-dipped galvanized steel pipes and cold electric galvanized options for effective cathodic protection.

Solid CRA, Clad, and Lined Pipes: Specialized solutions for extreme corrosive and abrasive challenges.

Rayoung: Your Global Partner in Piping Solutions

Strategically located in Cangzhou, China, a renowned hub for piping solutions, Rayoung stands as a leading supplier, exporter, and manufacturer union. We specialize in comprehensive piping solutions for the oil and gas industry, offering an extensive range of steel pipes, butt weld pipe fittings, and steel flanges.

Our dedication to quality, competitive pricing, and customer satisfaction has established us as a reliable partner for companies worldwide.

Ready to enhance your project with superior carbon steel piping solutions?

Please contact us now.

Tel/WhatsApp: +86-18003119682

Emails: info@hb-steel.com