Buttweld fittings are widely used in piping systems, primarily connecting two pipe sections through welding. They are primarily used in high-pressure piping systems and other high-pressure applications requiring high-pressure resistance and precise dimensions. These buttweld pipe fittings are meticulously designed to ensure stable and leak-tight connections, playing a vital role in various industrial environments.

They are used in industries such as petrochemicals, pharmaceuticals, healthcare, power generation, aerospace, defense, fire protection, metallurgy, shipbuilding, natural gas, nuclear power, and environmental protection.

Butt Weld Pipe Fitting Bevel

All welded pipe fittings have beveled ends to allow for ease of welding. This bevel allows for full penetration weld in most cases. There are two types of bevels:

Plain Bevel and Compound Bevel.

Buttweld Fitting Standards

- ASME B16.9: This is an internationally recognized standard established by the American Society of Mechanical Engineers (ASME). It covering factory-manufactured buttweld fittings, including elbows, tees, reducers, caps, and more. This standard specifies detailed technical requirements for pipe fitting dimensions, tolerances, pressure ratings, and other parameters, making it one of the most widely used standards globally.

- ASME B16.25 Buttwelding Ends

Specifies the preparation of buttwelding ends of piping components to be joined into a piping system by welding. It’s commonly used in conjunction with ASME B16.9 for carbon steel fittings. - ASME B16.28: This standard primarily addresses small-radius welded elbows.

- ASTM A234 / A234M Standard Specification: for Piping Fittings of Wrought Carbon Steel and Alloy Steel for Moderate and High Temperature Service

Specifies requirements for wrought carbon steel and alloy steel fittings of seamless and welded construction. While an ASTM (American Society for Testing and Materials) standard, it’s frequently referenced in Australian projects for material specifications of buttweld fittings. - GB/T 12459: This is a Chinese national standard similar to ASME standards, specifying dimensions, tolerances, and technical requirements for welded seamless steel pipe fittings.

- GB/T 13401: This standard specifies the dimensions, tolerances, and technical requirements for welded steel pipe fittings.

- EN 10253: This is the primary European standard for buttweld fittings, divided into several parts, such as EN 10253-2 and EN 10253-4.

- DIN 2605 / DIN 2615 / DIN 2616 / DIN 2617: German standards for elbows, tees, reducers, and pipe caps.

- AS 2129 : Flanges for Pipes, Valves and Fittings

Though primarily focused on flanges, this standard is relevant for integrated piping systems that include buttweld fittings, detailing flange specifications that ensure compatibility and integrity of the overall system. - ANSI B36.10 , B36.19: butt weld pipe fittings dimensions standard.

Welded Pipe Fittings Common Materials:

- Carbon Steel Welded Fitting:

Carbon steel butt weld fittings are typically made from body materials in ASTM A234 WPB (most commonly) and WPC, MSS-SP-75 WPHY. The thickness usually is usually in line with schedule 40 steel pipe fittings, STD, or 80. The pressure class can range from 1500 psi, 2500 psi, 3000 psi, 6000 psi to 9000 psi. - Alloy steel butt weld fittings

Alloy steel butt weld fittings are typically made from materials such as ASTM A234 WP1, WP5, WP9, WP11, WP22, WP91, and so on. - Stainless Steel Butt Weld Fittings:

Stainless buttweld fittings are available in 316 and 304 grades.

Buttweld Fittings Types

| Fitting Type | Function Description | Common Types / Angles | Application Fields | Features & Notes |

| Elbow | Change the flow direction in a pipeline | 90°, 45°, 180° Long Radius, Short Radius | Oil, Gas, Chemical, Power, etc. | Used to change flow direction; available in LR and SR types |

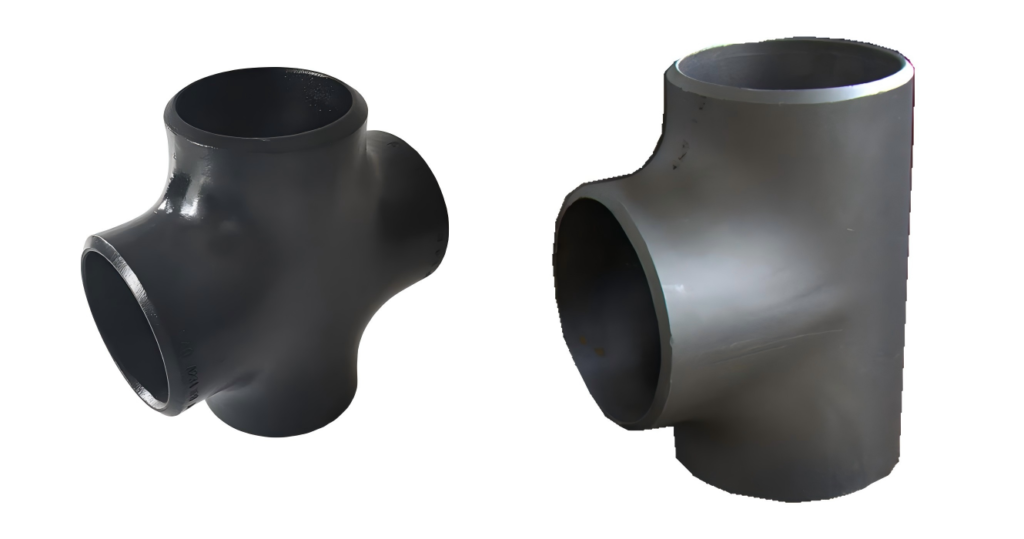

| Tee | Distribute or combine flow | Equal Tee, Reducing Tee | Branch piping layout | Connects branch pipelines; simple structure, easy installation |

| Cross | Connect multiple pipeline directions | Equal Cross, Reducing Cross | Chemical, Firefighting, Complex piping | Complex structure, stress-concentrated; requires proper installation layout |

| Reducer | Connect different pipe diameters | Concentric Reducer, Eccentric Reducer | Flow control, pump inlet, horizontal piping | Eccentric prevents fluid accumulation; concentric used for vertical piping |

| Cap | Close the end of a pipeline | Hemispherical, Elliptical | Pipe ends, test lines, reserved pipelines | Easy to install, ideal for sealing or testing ends |

Buttweld 90°+45°+180° Elbow Dimensions

| Nominal Size | Outside Diameter at Bevel | Center to End | Center to Center | Back to Face | |||||

| 90° Elbows | 45° Elbows | 180 Returns | |||||||

| DN | NPS | OD | A | B | O | K | |||

| LR | SR | LR | LR | SR | LR | SR | |||

| 15 | 1/2 | 21.3 | 38 | 16 | 76 | 48 | |||

| 20 | 3/4 | 26.7 | 38 | 19 | 76 | 51 | |||

| 25 | 1 | 33.4 | 38 | 25 | 22 | 76 | 51 | 56 | 41 |

| 32 | 1 1/4 | 42.2 | 48 | 32 | 25 | 95 | 64 | 70 | 52 |

| 40 | 1 1/2 | 48.3 | 57 | 38 | 29 | 114 | 76 | 83 | 62 |

| 50 | 2 | 60.3 | 76 | 51 | 35 | 152 | 102 | 106 | 81 |

| 65 | 2 1/2 | 73.0 | 95 | 64 | 44 | 190 | 127 | 132 | 100 |

| 80 | 3 | 88.9 | 114 | 76 | 51 | 229 | 152 | 159 | 121 |

| 90 | 3 1/2 | 101.6 | 133 | 4、89 | 57 | 267 | 178 | 184 | 140 |

| 100 | 4 | 114.3 | 152 | 102 | 64 | 305 | 203 | 210 | 159 |

| 125 | 5 | 141.3 | 190 | 127 | 79 | 381 | 254 | 262 | 197 |

| 150 | 6 | 168.3 | 229 | 152 | 95 | 457 | 305 | 313 | 237 |

| 200 | 8 | 219.1 | 305 | 203 | 127 | 610 | 406 | 414 | 313 |

| 250 | 10 | 273.0 | 381 | 254 | 159 | 762 | 508 | 518 | 391 |

| 300 | 12 | 323.8 | 457 | 305 | 190 | 914 | 609 | 619 | 467 |

| 350 | 14 | 355.6 | 533 | 356 | 222 | 1067 | 711 | 711 | 533 |

| 400 | 16 | 406.4 | 610 | 406 | 254 | 1219 | 813 | 813 | 610 |

| 450 | 18 | 457.0 | 686 | 457 | 286 | 1372 | 914 | 914 | 686 |

| 500 | 20 | 508.0 | 762 | 508 | 318 | 1524 | 1016 | 1016 | 762 |

| 550 | 22 | 559.0 | 838 | 559 | 343 | 1676 | 1118 | 1118 | 838 |

| 600 | 24 | 610.0 | 914 | 610 | 381 | 1829 | 1219 | 1219 | 914 |

| 650 | 26 | 660.0 | 991 | 660 | 406 | ||||

| 700 | 28 | 711.0 | 1067 | 711 | 438 | ||||

| 750 | 30 | 762.0 | 1143 | 762 | 470 | ||||

| 800 | 32 | 813.0 | 1219 | 813 | 502 | ||||

| 850 | 34 | 864.0 | 1295 | 864 | 533 | ||||

| 900 | 36 | 914.0 | 1372 | 914 | 565 | ||||

| 950 | 38 | 965.0 | 1448 | 965 | 600 | ||||

| 1000 | 40 | 1016.0 | 1524 | 1016 | 632 | ||||

| 1050 | 42 | 1067.0 | 1600 | 1067 | 660 | ||||

| 1100 | 44 | 1118.0 | 1676 | 1118 | 695 | ||||

| 1150 | 46 | 1168.0 | 1753 | 1168 | 727 | ||||

| 1200 | 48 | 1219.0 | 1829 | 1219 | 759 | ||||

Buttweld Tee & Cross Dimensions

| Nominal Size | Outside Diameter at Bevel | Center to End | ||

| DN | NPS | OD1×OD2 | C | M |

| 15 | 1/2 | 21.3 | 25 | 25 |

| 20 | 3/4 | 26.7 | 29 | 29 |

| 25 | 1 | 33.4 | 38 | 38 |

| 32 | 11/4 | 42.2 | 48 | 48 |

| 40 | 11/2 | 48.3 | 57 | 57 |

| 50 | 2 | 60.3 | 64 | 64 |

| 65 | 21/2 | 73.0 | 76 | 76 |

| 80 | 3 | 88.9 | 86 | 86 |

| 90 | 31/2 | 101.6 | 95 | 95 |

| 100 | 4 | 114.3 | 105 | 105 |

| 125 | 5 | 141.3 | 124 | 124 |

| 150 | 6 | 168.3 | 143 | 143 |

| 200 | 8 | 219.1 | 178 | 178 |

| 250 | 10 | 273.0 | 216 | 216 |

| 300 | 12 | 323.8 | 254 | 254 |

| 350 | 14 | 355.6 | 279 | 279 |

| 400 | 16 | 406.4 | 305 | 305 |

| 450 | 18 | 547.0 | 343 | 343 |

| 500 | 20 | 508.0 | 381 | 381 |

| 550 | 22 | 559.0 | 419 | 419 |

| 600 | 24 | 610.0 | 432 | 432 |

| 650 | 26 | 660.0 | 495 | 495 |

| 700 | 28 | 711.0 | 521 | 521 |

| 750 | 30 | 762.0 | 559 | 559 |

| 800 | 32 | 813.0 | 597 | 597 |

| 850 | 34 | 864.0 | 635 | 635 |

| 900 | 36 | 914.0 | 673 | 673 |

| 950 | 38 | 965.0 | 711 | 711 |

| 1000 | 40 | 1016.0 | 749 | 749 |

| 1050 | 42 | 1067.0 | 762 | 711 |

| 1100 | 44 | 1118.0 | 813 | 762 |

| 1150 | 46 | 1168.0 | 851 | 800 |

| 1200 | 48 | 1219.0 | 889 | 838 |

| 1300 | 52 | 1321.0 | 965 | 914 |

| 1400 | 56 | 1422.0 | 1041 | 965 |

| 1500 | 60 | 1524.0 | 1118 | 1016 |

| 1600 | 64 | 1626.0 | 1194 | 1092 |

| 1700 | 68 | 1727.0 | 1270 | 1168 |

| 1800 | 72 | 1829.0 | 1320 | 1245 |

| 1900 | 76 | 1930.0 | 1422 | 1320 |

| 2000 | 80 | 2032.0 | 1499 | 1397 |

Buttweld Reducer Dimensions

| OD1 | OD2 | END TO END |

| NPS | NPS | H |

| 3/4 | 3/8 – 1/2 | 38 |

| 1 | 1/2 – 3/4 | 51 |

| 1 1/4 | 1/2 – 1 | 51 |

| 1 1/2 | 1/2 – 1 1/4 | 64 |

| 2 | 3/4 – 1 1/2 | 76 |

| 2 1/2 | 1 – 2 | 89 |

| 3 | 1 1/4 – 2 1/2 | 102 |

| 4 | 2 – 3 1/2 | 102 |

| 5 | 2 – 4 | 127 |

| 6 | 2 1/2 – 5 | 140 |

| 8 | 3 1/2 – 6 | 152 |

| 10 | 4 – 8 | 178 |

| 12 | 5 – 10 | 203 |

| 14 | 6 – 12 | 330 |

| 16 | 6 – 14 | 356 |

| 18 | 8 – 16 | 381 |

| 20 | 10 – 18 | 508 |

| 22 | 12 – 20 | 508 |

| 24 | 12 – 22 | 508 |

| 26 | 12 – 24 | 610 |

| 28 | 14 – 26 | 610 |

| 30 | 14 – 28 | 610 |

| 32 | 20 – 30 | 610 |

| 34 | 22 – 32 | 610 |

| 36 | 22 – 34 | 610 |

| 38 | 24 – 36 | 610 |

| 40 | 28 – 38 | 610 |

| 42 | 28 – 40 | 610 |

| 44 | 32 – 42 | 610 |

| 46 | 34 – 44 | 711 |

| 48 | 36 – 46 | 711 |

| 52 | 40 – 48 | 711 |

| 56 | 40 – 52 | 711 |

| 60 | 44 – 56 | 711 |

Buttweld Cap Dimensions

| Nominal Size | Outside Diameter at Bevel | Length | Limiting Wall Thickness for Length E | ||

| DN | NPS | OD | E | E1 | |

| 15 | 1/2 | 21.3 | 25 | 25 | 4.57 |

| 20 | 3/4 | 26.7 | 25 | 25 | 3.81 |

| 25 | 1 | 33.4 | 38 | 38 | 4.57 |

| 32 | 1 1/4 | 42.2 | 38 | 38 | 4.83 |

| 40 | 1 1/2 | 48.3 | 38 | 38 | 5.08 |

| 50 | 2 | 60.3 | 38 | 44 | 5.59 |

| 65 | 2 1/2 | 73.0 | 38 | 51 | 7.11 |

| 80 | 3 | 88.9 | 51 | 64 | 7.62 |

| 90 | 3 1/2 | 101.6 | 64 | 76 | 8.13 |

| 100 | 4 | 114.3 | 64 | 76 | 8.64 |

| 125 | 5 | 141.3 | 76 | 89 | 9.65 |

| 150 | 6 | 168.3 | 89 | 102 | 10.92 |

| 200 | 8 | 219.1 | 102 | 127 | 12.7 |

| 250 | 10 | 273.0 | 127 | 152 | 12.70 |

| 300 | 12 | 323.8 | 152 | 178 | 12.70 |

| 350 | 14 | 355.6 | 165 | 191 | 12.70 |

| 400 | 16 | 406.4 | 178 | 203 | 12.70 |

| 450 | 18 | 457.0 | 203 | 229 | 12.70 |

| 500 | 20 | 508.0 | 229 | 254 | 12.70 |

| 550 | 22 | 559.0 | 254 | 254 | 12.70 |

| 600 | 24 | 610.0 | 267 | 305 | 12.70 |

| 650 | 26 | 660.0 | 267 | ||

| 700 | 28 | 711.0 | 267 | ||

| 750 | 30 | 762.0 | 267 | ||

| 800 | 32 | 813.0 | 267 | ||

| 850 | 34 | 864.0 | 267 | ||

| 900 | 36 | 914.0 | 267 | ||

| 950 | 38 | 965.0 | 305 | ||

| 1000 | 40 | 1016.0 | 305 | ||

| 1050 | 42 | 1067.0 | 305 | ||

| 1100 | 44 | 1118.0 | 343 | ||

| 1150 | 46 | 1168.0 | 343 | ||

| 1200 | 48 | 1219.0 | 343 | ||

Buttweld Manufacturer and Origin Options

Rayoung is one of the largest manufacturers of domestic carbon steel butt weld fittings and flanges.

Our company specializes in the design, manufacture, and supply of various types of buttweld fittings. Our products cover a wide range of materials, including carbon steel, stainless steel, and alloy steel to meet the needs of different operating conditions. Our products are available in a wide range of sizes, from conventional small diameters to large diameters, and are suitable for harsh operating conditions such as high temperatures, high pressures, and strong corrosion

References

The following links provide good resources on welded pipe fittings:

jsfittings.com