What is a buttweld fitting?

Simply put, buttweld fittings are components used to connect or alter sections of pipes in industrial and commercial setups. Unlike threaded or socket-weld alternatives, butt weld fittings are welded directly to the pipe, creating a continuous, leak-proof structure that is as strong as the pipe itself.

The Function of Butt Weld Pipe Fittings

Butt weld fittings are fundamental components used across demanding industries such as oil and gas, power generation, chemical processing, and shipbuilding. Their primary purpose is to alter the geometry of a pipeline. This includes changing the direction of flow, joining pipes of different sizes, or creating branches from a main line. The seamless connection achieved through buttwelding offers significant advantages, including optimized fluid flow, minimal pressure drop, and exceptional resistance to mechanical stress and vibration.

An Overview of Butt Weld Fitting Types

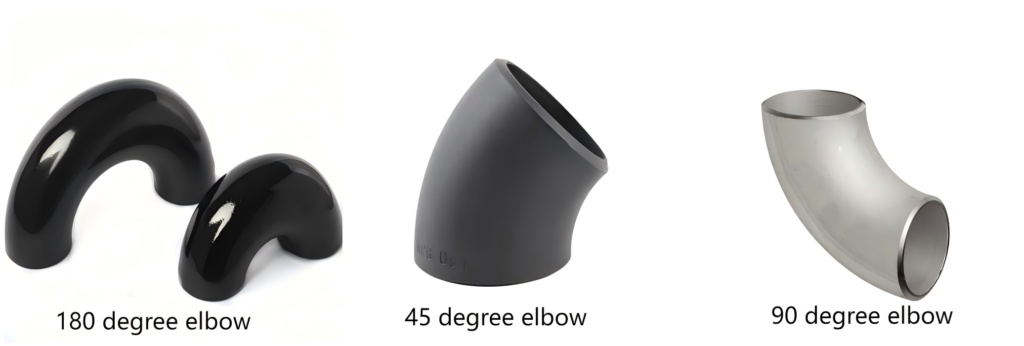

1. Elbows

Elbows are among the most frequently used fittings, designed to change the direction of a pipeline. They are typically available in 45°, 90°, and 180° angles.

Long Radius (LR) Elbows: These have a gentle curve with a radius of curvature equal to 1.5 times the pipe diameter. They are preferred in applications where minimizing pressure drop and turbulence is critical.

Short Radius (SR) Elbows: With a sharper turn and a radius equal to the pipe diameter, SR elbows are used in tight or confined spaces where a compact layout is necessary.

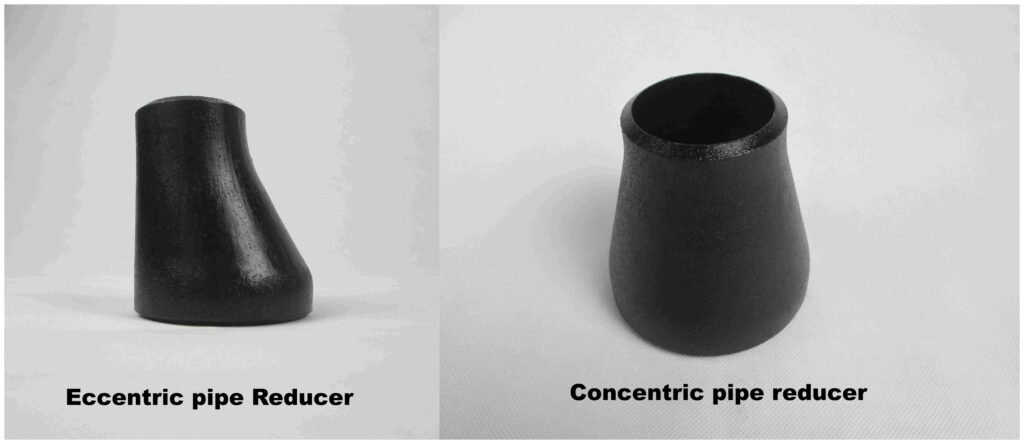

2. Reducers

Reducers are essential for connecting two pipes with different diameters, ensuring a smooth transition that maintains flow velocity and pressure.

Concentric Reducers: This cone-shaped fitting keeps the centerline of both pipes aligned. It is typically used in vertical pipe runs.

Eccentric Reducers: This type has one flat side, offsetting the centerline. It is used in horizontal pipelines to prevent the accumulation of air at the top or liquid at the bottom of the pipe, which is especially important for pump suction lines.

3. Tees

Tees are T-shaped fittings are used to create a 90-degree branch from a main pipeline, allowing flow to be combined or distributed.

Equal Tees: All three openings on this fitting are the same diameter, resulting in an even split of flow.

Reducing Tees: The branch port is smaller than the main run ports, making it ideal for connecting smaller-diameter branch lines.

4. End Caps

Butt weld Pipe end caps are simple but crucial fittings used to seal the end of a pipeline. They are welded onto the terminus of a pipe to stop flow permanently and ensure a leak-proof seal, often for future expansion points or as a safety measure.

5. Crosses

A cross fitting, also known as a four-way fitting, has one inlet and three outlets (or vice-versa). While less common than tees, crosses are useful in systems that require a multi-directional flow from a single point, such as in fire sprinkler systems or some process fluid distribution headers.

6. Pipe Bends

Similar to elbows, bends create a change in direction but are characterized by a much larger radius. They are often custom-fabricated for specific applications, such as long-distance pipelines, where their gradual curve minimizes friction and allows for the passage of inspection tools (known as “pigs”).

Key Advantages of Butt Weld Fittings

The widespread use of butt weld fittings in critical applications is due to their distinct advantages:

Exceptional Strength and Durability: The welded joint becomes an integral part of the pipe, offering a connection that can withstand high pressures, extreme temperatures, and significant mechanical forces.

Optimized Flow Dynamics: The smooth inner surface of a butt weld fitting matches the pipe’s bore, eliminating sharp edges or obstructions. This ensures an uninterrupted flow path, which minimizes pressure drop and reduces turbulence and erosion.

Leak-Proof Integrity: By fusing the fitting directly to the pipe, the connection is monolithic and free from potential leak paths, a critical feature for transporting hazardous or valuable fluids.

Versatility in Materials: Butt weld fittings are available in a comprehensive range of materials, including carbon steel, stainless steel, and specialized alloys, providing flexibility to meet the demands of any application.

Cost-Effectiveness: While the initial installation requires skilled labor, the long-term reliability and low maintenance requirements of butt weld fittings make them a highly economical choice over the life of the system.

In summary, a butt weld pipe fitting is far more than a simple connector; it is an engineered component that guarantees the integrity, efficiency, and safety of a piping system. Understanding the different types and their specific applications enables engineers and designers to select the ideal solution for their needs, ensuring a reliable and long-lasting infrastructure.

RAYOUNG is a China butt weld fittings factory and exporter, we provide the high quality butt weld fittings for different industrial application, please contact us if you need it.