In the complex world of industrial piping, the integrity of a system is only as strong as its fittings. While pipes transport the media, it is the fittings that direct, control, and terminate the flow.

Among these, the Butt Weld Pipe Cap plays a critical, albeit understated, role in ensuring safety and system pressure.

Also known in the industry as pipe heads, plugs, bulkheads, or covers, these components are the standard solution for permanently closing pipe ends.

Whether you are in the oil & gas sector, chemical processing, or power generation, understanding the specifications and material grades of high-quality pipe caps is essential for project success.

What is a Butt Weld Pipe Cap?

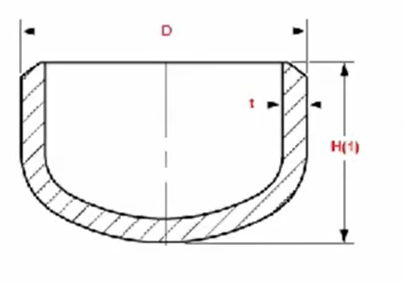

A Butt Weld Pipe Cap is a fitting welded to the open end of a pipe to block the flow of fluids or gases. It functions similarly to a pipe plug but is designed for larger, high-pressure, and permanent applications.

Unlike threaded fittings which can be unscrewed, a butt weld cap provides a permanent, leak-proof seal. The cap is beveled to match the pipe end, allowing for a full-penetration weld. This design ensures that the connection point is as strong as the pipe itself, capable of withstanding extreme pressure, vibration, and thermal cycling.

Why Choose Butt Weld Caps?

Zero Leakage: The welded connection eliminates potential leak paths found in threaded connections.

Structural Strength: The semi-ellipsoidal shape distributes stress evenly, making it ideal for high-pressure environments.

Contamination Prevention: It acts as a heavy-duty shield, preventing dust, moisture, and debris from entering the pipeline during maintenance or expansion.

Technical Specifications

When sourcing pipe caps, precision is key. Our range of Butt Weld Pipe Caps is manufactured to meet rigorous international standards, ensuring compatibility with your existing piping systems.

Below are the detailed specifications available for global procurement:

1. Size Range

We cater to projects of all scales, from small-bore instrumentation lines to massive transmission pipelines.

Size: 1/2” to 72” (DN15 to DN1800)

2. Pressure Ratings & Wall Thickness

Our caps are designed to handle everything from standard low-pressure water systems to critical high-pressure steam lines.

Schedules: Sch5, Sch10, Sch20, Sch40, STD, Sch80, XS, Sch120, Sch160, XXS.

3. Manufacturing Standards

To ensure safety and interchangeability, our products comply with major global industrial standards:

Standards: ANSI, ISO, JIS, DIN, BS, GB, SH, HG, QOST.

Material Grades: Built for Every Environment

Selecting the right material is crucial for preventing corrosion and ensuring longevity. We offer a comprehensive selection of materials to suit specific media and environmental conditions.

Carbon Steel Pipe Caps

The workhorse of the industry, ideal for general oil, gas, and water transport.

Standards: ASTM A234 WPB, A420 WPL3, A420 WPL6, MSS-SP-75.

High-Yield Grades: WPHY 42 / 46 / 52 / 56 / 60 / 65 / 70.

Stainless Steel Pipe Caps

Perfect for corrosive environments, food processing, and chemical applications requiring purity and rust resistance.

Standards: ASTM A403.

Grades: WP304, 304L, 304H, 316, 316L, 317, 317L, 321, 310, 347.

Super Austenitic: 904L.

Alloy Steel Pipe Caps

Engineered for high-temperature and high-pressure service, often used in power plants and heat exchangers.

Standards: ASTM A234.

Grades: WP1, WP5, WP9, WP11, WP22, WP91.

Buttweld cap Applications Across Industries:

Due to their robust construction and material versatility, Butt Weld Pipe Caps are indispensable in the following sectors:

1. Petroleum & Gas: Sealing transmission lines and refineries.

2. Chemical Industry: Safely containing aggressive acids and alkalis.

3. Power Generation: Used in nuclear power plants and thermal steam lines (high-pressure alloy caps).

4. Construction: Structural piping and HVAC systems.

5. Shipbuilding: Marine piping systems requiring salt-water corrosion resistance.

6. Water Treatment: Large diameter caps for municipal water supply networks.

Please click to the buttweld caps uses.

Conclusion

Whether you call them pipe heads, covers, or butt weld caps, these fittings are vital for the safety and integrity of your pipeline. By choosing the correct material grade and pressure schedule, you ensure the longevity of your system and the safety of your personnel.

Looking for high-quality Butt Weld Pipe Caps?

We supply a complete range of Carbon, Stainless, and Alloy steel caps tailored to your project needs.

Contact us today for a quote or technical consultation.

info@hb-steel.com

+86-18003119682