Butt weld fittings are one of the most popular connection types in pipeline systems. It has always been required in massive quantities in different industries, especially for the large diameter pipelines, mainly used to change direction, branch off, or mechanically join equipment to the system.

Butt welded Pipe fittings, such as carbon steel and stainless steel, offer many advantages compared to threaded and socket weld fittings. While socket weld fittings are only available up to a specific size, butt weld fittings are available in sizes ranging from 1/2 inch to 72 inches.

Butt welded Fittings Essential Material Specifications

To satisfy the rigorous demands of various industries, butt weld fittings are manufactured from highly durable materials. The most prevalent options include:

- Carbon Steel

- Stainless Stee

- Alloy Steel

RAYONG is one of the largest distributors of pipe flanges and butt weld fittings in China. We offer an extensive selection of premium butt weld fittings, available in both welded and seamless types to meet diverse industrial needs.

Primary Types of Butt Weld Fittings

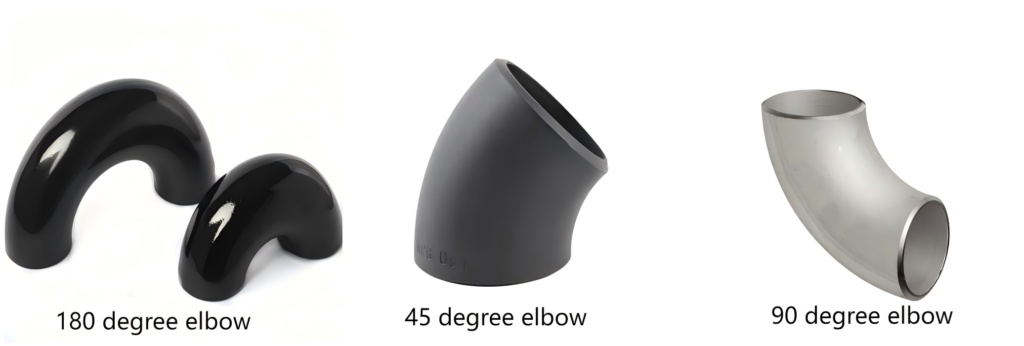

Butt weld Elbow in 45 degree,90 degree or 180 degree.

Butt weld Tee and Reducing Tee, Reducer, Cap, Cross.

Butt weld Elbow

Butt weld elbow is used to change the fluid direction in pipeline systems. There are two types: long radius (LR) and short radius (SR). Butt weld elbows are available in different degrees, including 45 degrees, 90 degrees, and 180 degrees. So, there are:

LR 45 degree butt weld elbow,LR 90 degree elbow, SR 45 degree elbow,SR 90 degree elbow,180 degree steel pipe elbow.

(Elbows with a degree greater than 90 degrees are commonly referred to as steel bends. For example, LR/SR 180-degree bends.)

Butt Weld Tee

A butt weld tee is utilized to establish a 90-degree branch from the main pipeline.

Equal Tee: The branch diameter is identical to the main pipe’s diameter.

Reducing Tee: The branch diameter is smaller than the main pipe, which is beneficial for connecting smaller pipes or instrumentation.

Butt Weld Reducer

A buttweld reducer is used to modify the pipe’s diameter, which aids in controlling the fluid’s flow rate and velocity.

Concentric Reducer: This type has a conical shape and shares a common centerline for both pipe ends

Eccentric Reducer: This reducer features offset centerlines, which is perfect for maintaining the top or bottom level of the pipe and preventing the trapping of air or debris.

Butt Weld Cap

Butt weld Cap: A straightforward fitting designed to seal the end of a pipe.

Butt Weld Cross

Buttweld Cross: A four-way fitting that establishes two 90-degree branches from a single point.

Butt weld fittings have beveled ends treatment

All butt weld fittings have beveled ends in accordance with ASME B16.25 standards.

This design facilitates a strong, full-penetration weld without the need for additional on-site preparation.

Butt weld fittings Applications

Due to Butt weld fittings’ strength and dependability, butt weld fittings are trusted across a multitude of industries, including:

- Oil and Gas

- Petrochemical Facilities

- Chemical Processing

- Waste Treatment Plants

- Power Generation (including nuclear)

- Paper and Pulp Production

- Gas Processing

- etc.

Principal Advantages

Choosing butt weld fittings offers several considerable benefits for any piping system.

- Strong and Leak-Proof: The welded connection becomes an integral part of the pipe, forming a continuous metal structure that is both exceptionally strong and impervious to leaks

- Efficient Flow: A smooth inner surface and gradual changes in direction minimize pressure drops and turbulence within the pipe, optimizing flow.

- High-Performance: These fittings are engineered to withstand high pressures and extreme temperatures in demanding environments.

- Long-Term Durability: They provide excellent resistance to corrosion and erosion, making them a lasting and cost-effective choice.

- Space-Saving Design: A welded piping system typically occupies less space than systems using other connection methods.

While the installation process necessitates a skilled welder, the superior strength and long-term reliability of butt weld fittings make them the industry standard for critical applications.

Supply of Buttweld Fittings

Here at Rayoung, we have worked with specialist mills and traders for many years to export the high-quality and reliable buttweld fittings. We have a variety of different fixtures available in different sizes and materials

All our products are fully tested to international standards so you can be safe in the knowledge that you are buying high quality products. Speak to our sales team today.