In industrial piping systems, flanges provide the essential connections that join pipes, valves, pumps, and other equipment. Among the various types available, weld neck flanges and slip-on flanges are two of the most common and widely used. However, they serve distinctly different purposes and are not interchangeable. Selecting the wrong type can lead to system failures, leaks, and safety hazards.

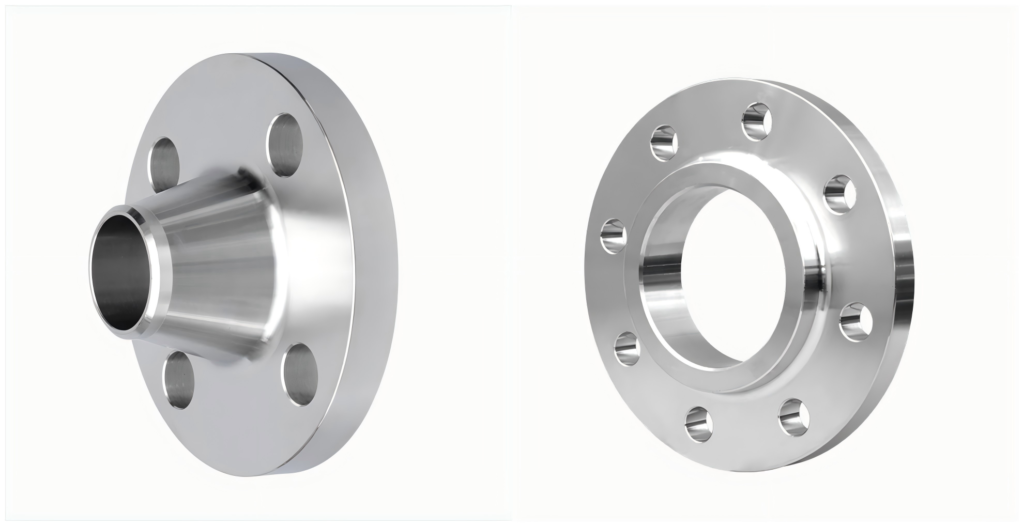

What is the Slip-On Flange?

A Slip-On flange is designed to slide over the outer diameter of a pipe. It is then welded both inside and outside to create a seal. Because of its simple design, it is a popular, cost-effective choice for many industrial applications.

Slip-On Flange Applications:

Water Systems: Ideal for standard water distribution lines.

HVAC: Widely used in heating and cooling systems.

Food & Beverage: Perfect for low-pressure lines that require frequent cleaning.

Basic Chemical Lines: Used for non-hazardous fluid transport.

What is the Weld Neck Flange?

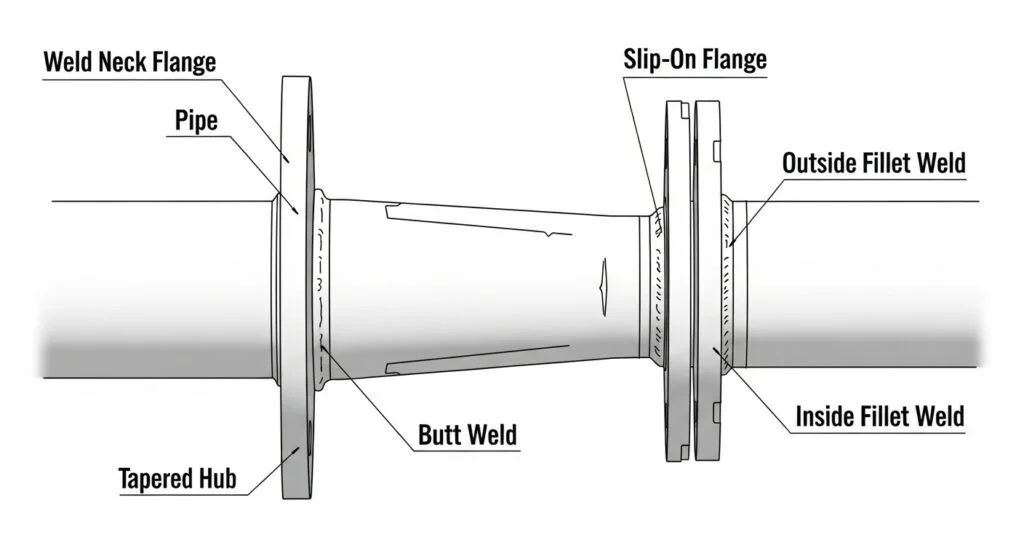

Weld Neck flanges are easily recognized by their long, tapered hub. This hub is butt-welded directly to the pipe. This design is the industry standard for high-pressure, high-temperature, and critical-service environments.

Weld Neck Flange Applications:

Oil & Gas: Used in pipelines for crude oil and natural gas, where pressure is extreme.

Petrochemical Plants: Essential for handling corrosive or hazardous chemicals safely.

Power Generation: Vital for high-pressure steam lines in power plants.

Offshore Rigs: Built to withstand harsh marine environments and mechanical stress.

| Feature | Weld Neck Flange | Slip-On Flange |

|---|---|---|

| Design & Structure | Long, tapered hub that is butt-welded to the pipe. | Slides over the pipe and is secured with two fillet welds. |

| Strength & Pressure Rating | Excellent strength and durability; suitable for high-pressure and high-temperature applications. | Moderate strength; best for low to medium pressure systems. |

| Fatigue Life | Excellent; can withstand cyclic loading and stress. | Approximately one-third that of a weld neck flange; poor for frequent stress cycles. |

| Leak Resistance | Superior, due to the robust butt-weld and tapered hub that reduces stress. | Moderate; the double welds can introduce potential weak points over time. |

| Cost | Higher initial cost due to more material and complex welding. | Lower initial cost and less expensive to install. |

| Installation Complexity | Requires skilled labor for precise alignment and butt-welding. | Easier and faster to install, requiring less precision. |

| Inspection | Butt weld can be radiographed (X-rayed) for quality assurance. | Fillet welds are difficult to inspect properly with radiography. |

Technical Comparison: Key Differences

Design and Strength

Weld Neck flanges: The tapered hub acts as a bridge. it transfers stress from the flange to the pipe. This reinforcement helps the joint handle vibration, pressure surges, and heavy mechanical loads.

Slip-On flanges: These have a lower profile and no tapered hub. They rely entirely on fillet welds. While functional, they do not offer the same structural support as a Weld Neck flange

Welding and Quality Inspection

Butt-Weld (WN)flanges : This flange requires a full-penetration butt weld. The biggest advantage? This weld can be X-rayed (Radiographic Testing). This allows inspectors to verify the internal quality of the weld, making it the safest choice for high-risk systems.

Fillet Weld (SO)flanges : A Slip-On flange needs two welds—one on the outside hub and one on the inside. However, these welds are difficult to X-ray. It is much harder to guarantee the internal integrity of the joint.

Reliability in Harsh Conditions

Fatigue Resistance: In systems with constant temperature changes or vibrations, Weld Neck flanges last about three times longer than Slip-On flanges.

Corrosion Issues: Slip-On flanges have a small gap between the pipe and the bore. Corrosive fluids can settle in this gap, leading to “crevice corrosion.” Weld Neck flanges provide a smooth, continuous flow, eliminating this risk.

Cost: Initial vs. Lifetime

Initial Cost: Slip-On flanges are cheaper to buy and easier to align. This reduces the upfront labor and material costs.

Long-Term Value: Weld Neck flanges cost more initially. However, they rarely fail. In the long run, they save money by preventing leaks, unplanned shutdowns, and expensive repairs.

Frequently Asked Questions (FAQ)

Q1: Can I use a Slip-On flange for high-pressure lines to save money?

No. Slip-On flanges are only about two-thirds as strong as Weld Neck flanges under internal pressure. Using them in high-pressure systems is a major safety risk.

Q2: What is the purpose of the “Neck” on a Weld Neck flange?

The neck provides a gradual transition of thickness. This prevents stress from concentrating at the weld, which is usually the weakest point in a piping system.

Q3: Are Slip-On flanges allowed in refineries?

Usually, they are restricted to “utility” lines like air or water. For lines carrying oil, gas, or chemicals, most engineers require Weld Neck flanges.

Q4: Do these flanges use the same faces?

Yes. Both can be made with Raised Face (RF) or Flat Face (FF). However, for very high pressures, Weld Neck flanges are often paired with Ring-Type Joint (RTJ) faces for a tighter seal.

Q5: Why is X-raying welds so important?

In B2B industrial projects, a single leak can cost millions. X-rays (Radiography) allow us to see inside the weld to ensure there are no cracks or holes. This is only possible with the butt-weld design of the Weld Neck flange.

Expert Solutions for Your Piping Needs

Selecting the right flange depends on your project’s pressure, temperature, and budget. At Rayoung, we manufacture a full range of forged flanges that meet global standards like ASME, DIN, and EN.

Need a technical consultation or a bulk quote? Contact our engineering team today to ensure your system is built to last.