In critical piping systems—those handling high pressure, extreme temperatures, or hazardous fluids—the Weld Neck Flange (WN) is the most widely trusted component. But what makes it so indispensable compared to other types?

Whether you are a procurement manager for an EPC project or a piping engineer, understanding the technical nuances of WN flanges is key to system integrity.

What is a Weld Neck Flange?

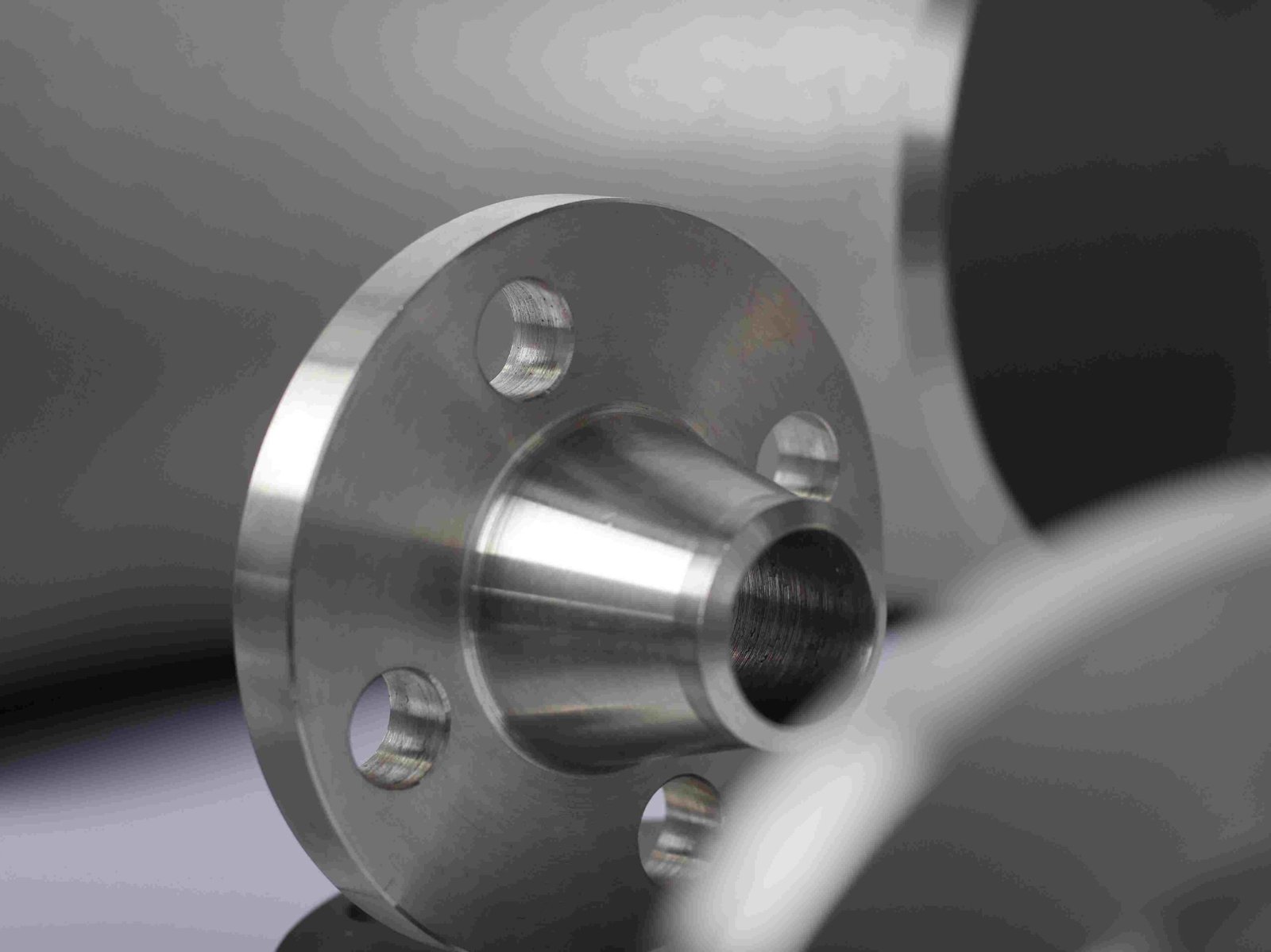

A Weld Neck Flange (often abbreviated as WN flange) is a forged fitting designed to be joined to a piping system by butt welding. It is easily identified by its long, tapered “neck” (hub) that transitions gradually from the flange thickness to the pipe wall thickness.

This tapered hub is not just for aesthetics; it provides vital reinforcement, allowing the flange to withstand high-pressure “surges” and mechanical stress.

What is the Purpose of a Weld Neck Flange?

The primary purpose of a weld neck flange is to transfer stress from the flange to the pipe itself. This design achieves several critical goals:

Stress Distribution: The tapered hub reduces high stress concentration at the base of the flange.

Turbulence Reduction: Since the internal diameter (ID) of the flange matches the ID of the pipe, there is no restriction in flow, which minimizes turbulence and erosion.

Extreme Conditions: It is the “go-to” choice for sub-zero temperatures or high-heat environments where the metal must expand and contract without cracking at the joints.

How Are Weld Neck Flanges Made?

Quality starts with the manufacturing process. At Rayoung, we follow a rigorous forging sequence:

Cutting & Heating: Steel billets (Carbon, Stainless, or Alloy) are cut and heated to forging temperatures (approx. 1100°C–1250°C).

Forging: The heated metal is shaped using heavy industrial hammers or presses. This ensures that the grain flow of the steel follows the shape of the flange, thereby increasing its mechanical strength.

Rolling & Piercing: The ring is formed, and the center is pierced to create the bore.

Machining: The flange is precision-machined on CNC lathes to meet ASME B16.5 or EN1092-1 tolerances, including the critical welding bevel.

Heat Treatment: Depending on the material (e.g., ASTM A105 or A182), flanges undergo normalizing or quenching and tempering to achieve the required hardness and ductility.

How to Fit Up a Weld Neck Flange?

“Fit-up” is the process of aligning the flange with the pipe before welding. For a WN flange, precision is non-negotiable:

Check the Bevel: Ensure the welding end of the flange and the pipe both have a 37.5-degree bevel (standard for walls over 5mm).

Alignment: Use a “Flange Square” or “Two-Hole Pins” to ensure the bolt holes are perfectly aligned (usually “straddling” the vertical center line).

The Root Gap: Leave a gap (typically 1.6mm to 3.2mm) between the pipe and the flange hub. This “root gap” allows for full weld penetration.

Tack Welding: Apply small tack welds at four points (12, 6, 3, and 9 o’clock) to hold the alignment before the final pass.

How to Weld a Weld Neck Flange to a 45-Degree Elbow?

Welding a WN flange directly to a 45° elbow is common in tight-space piping manifolds. Here is the professional approach:

Step 1: Bevel Match. Ensure the schedule (wall thickness) of the WN flange hub matches the schedule of the 45° elbow perfectly.

Step 2: Gap & Tack. Use a specialized welding clamp to hold the elbow and flange. Because the elbow is angled, ensure the flange face remains perpendicular to the required flow line.

Step 3: Root Pass. Use TIG (GTAW) for the root pass to ensure a smooth internal bead. This is vital to prevent turbulence.

Step 4: Filler Passes. Complete the weld using Stick (SMAW) or MIG (GMAW).

Pro Tip: Always perform a Dye Penetrant Test (PT) or Ultrasonic Test (UT) on the joint, especially if the system operates under high pressure.

Weld Neck Flange vs. Slip-On Flange

| Feature | Weld Neck Flange (WN) | Slip-On Flange (SO) |

| Connection Type | Butt-Weld (Single joint) | Fillet Weld (Internal & External) |

| Strength | Superior (High stress/fatigue resistance) | Moderate |

| Installation Cost | Higher (Requires skilled welding) | Lower (Easier to align) |

| Bore Match | Perfectly matches pipe ID | Slightly larger than pipe OD |

| Pressure Rating | Ideal for Class 900 and above | Generally used for Class 150 – 600 |

Need High-Quality WN Flanges for Your Next Project?

At Rayoung, we specialize in forged weld neck flanges that meet the strictest international standards (ASME, DIN, JIS). From standard carbon steel A105 to high-nickel alloys, we provide full MTC 3.1 certification and third-party inspection.

Explore our WN Flange Product Range or Request a Quote Today.