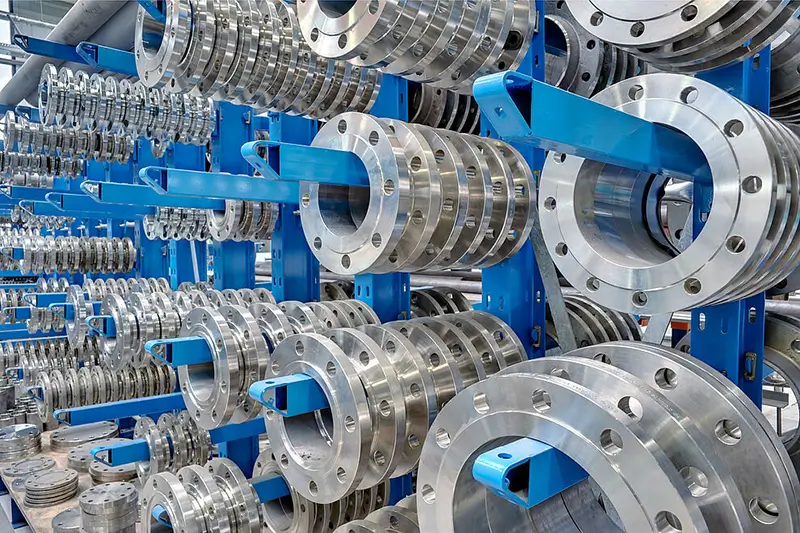

Flanges play an imperative part in pipeline frameworks, fundamentally serving as associations. Acting as the critical link between valves, steel pipes, and fittings, their integrity is non-negotiable. However, because they are metal components, they are highly susceptible to their environment. Improper storage often leads to rust, corrosion, and physical damage.

For both manufacturers and distributors, how you store your inventory is just as important as how you make it. This guide outlines the best strategies to ensure your flanges remain in perfect condition and are ready for safe installation.

1. Creating the Optimal Storage Environment

The golden rule for storing flanges is to keep them cool, dry, and clean. Moisture is the primary enemy, as humidity accelerates rusting. Additionally, you must avoid outdoor storage or areas exposed to direct sunlight, as extreme heat and UV rays can degrade certain material properties or protective coatings over time.

Key recommendations:

Keep it Dry: Maintain a low-humidity environment to prevent oxidation.

Ensure Ventilation: Good airflow prevents stagnant, damp air from settling on the metal.

Block UV Rays: Keep inventory away from direct sunlight to avoid temperature fluctuations.

2. Preparation: Cleaning and Drying

Throwing a dirty flange onto a shelf is a recipe for disaster. Dust, oil, and residual moisture trapped on the surface will inevitably lead to corrosion. Before storage, every flange needs to be prepped.

The 3-Step Process:

Inspect: Give the flange a quick visual check for existing defects.

Clean: Remove any dirt, grease, or water from the surface.

Dry & Coat: Allow the flange to air dry completely. For long-term storage, applying a thin layer of rust-proof oil is highly recommended.

3. Proactive Corrosion Protection

Sometimes a dry room isn’t enough. You need physical or chemical barriers to protect the metal. One of the most effective methods is using VCI (Vapor Corrosion Inhibitor) technology.

Protective measures to implement:

Coatings: These specialized coatings release corrosion-inhibiting vapors that form a molecular shield on the metal, protecting it even in slightly humid conditions.

Protective Caps/Covers: Use plastic flange covers to protect the sealing face and bolt holes from dust and impact.

Secure Fasteners: Ensure that any protective covers are securely fastened so they don’t fall off during shifting or transport.

4. Don’t “Set It and Forget It”: Regular Inspections

Warehouse conditions change. A roof leak, a spike in humidity, or accidental damage from forklifts can compromise your stock. Regular audits allow you to catch issues early.

What to look for:

Visual Scan: Are there signs of surface rust or scratches?

Layer Integrity: Are the protective oils or VCI coatings still intact?

Environment Check: Is the ventilation system working? Is the area still dry?

5. The Real Cost of Improper Storage

Neglecting storage protocols leads to financial loss and safety risks. A rusted flange cannot provide a tight seal, leading to leaks in the pipeline system. Furthermore, poor stacking can cause physical deformation, rendering the part useless.

The main risks:

Corrosion: Weakens the structural integrity and ruins the sealing surface.

Contamination: Dirt and grit can prevent a flush connection.

Physical Damage: Dents and dings from poor handling often mean the product must be scrapped.

For more industry insights or inquiries about high-quality steel flanges, please contact Rayoung—your trusted manufacturer and supplier in China.