Welding Neck Flange

Common outer diameters: 1/2”, 2”, 3”, 4”, 6”, 8”, 10”, 12” to 24”.

Product Name: Forged Weld Neck Flange (WN Flange)

Pressure Ratings: Class 150 to Class 2500, PN2.5 to PN 250

Materials: Carbon Steel, Stainless Steel, Alloy Steel

Standards: ASTM A105,A182 , ASME B16.5, B16.47, EN1092-1, DIN, JIS, GOST

(Inquiry response within 2 hours)

Production Description

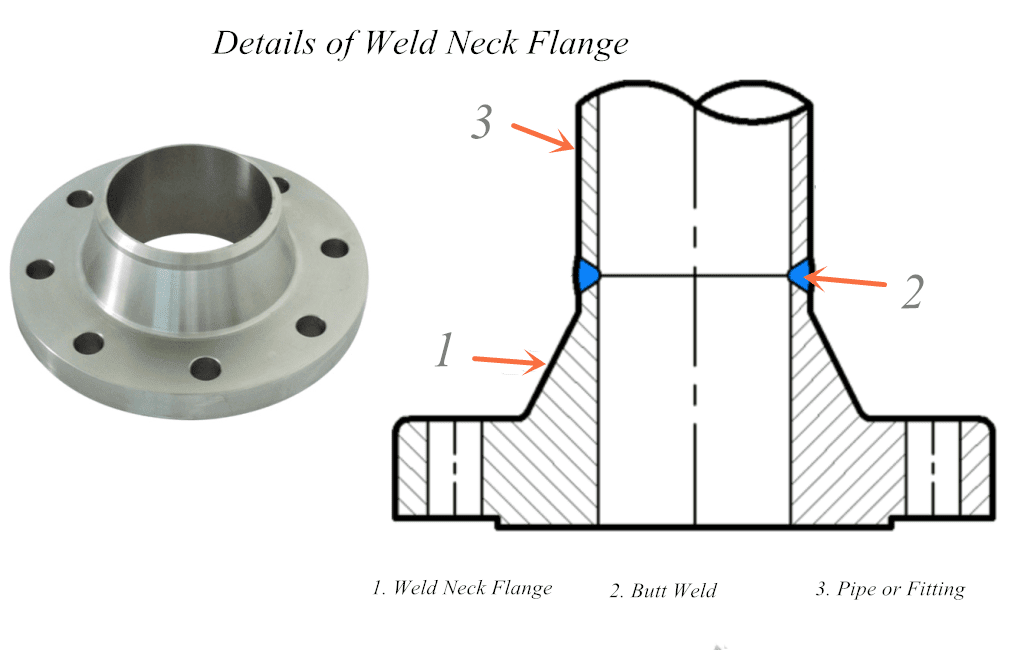

What is Welding neck flange?

Welding Neck Flanges (WN flanges) are distinguished by their long tapered hub, which provides critical reinforcement for high-pressure, sub-zero, or elevated temperature applications. The smooth transition from flange thickness to pipe wall thickness via the taper is extremely beneficial under conditions of repeated bending, caused by line expansion or other variable forces.

At Rayoung, our weld neck flanges are manufactured through a precision forging process, ensuring superior grain structure and mechanical strength to meet the rigorous demands of the Oil & Gas, Chemical, and Power Generation industries.

Detailed Specifications

| Feature | Specification Details |

| Size Range | 1/2″ to 60″ (DN15 to DN1500) or custom |

| Flange Face | RF (Raised Face), RTJ (Ring Type Joint), FF (Flat Face) |

| Carbon Steel | ASTM A105, A350 LF2, LF3, A694 F42/F52/F60/F65/F70 |

| Stainless Steel | ASTM A182 F304/304L, F316/316L, F321, F347, F51/F53 (Duplex) |

| Alloy Steel | ASTM A694 F42-F70, ASTM A182 F1, F5, F9, F11, F22, F91 |

| Wall Thickness | Sch5s to Sch160, XXS or customed |

| Coating/Treatment | Anti-rust Oil, Black Paint, Yellow Paint, Hot Dip Galvanized, Zinc Plated |

Standards for WN flanges:

ASTM A105 for carbon steel welding neck flanges.

ASTM A182 for alloy and stainless welding neck flange.

ASME B16.5

ASME B16.47

BS 3293

DIN 2630 PN 1 and PN 2.5, 2631 PN 6, 2632 PN 10, 2634 PN 16, 2634 PN 25, 2635 PN 40

Before ordering the weld neck flange, the companies shall need to confirm the material standard, outer diameter, pressure class, face type and thickness schedule.

A standard description for a welding neck flange is: “Flange, 10” Weld Neck, Class 150, RF, Schedule 40, ASTM A105 ASME B 16.5.”

Common materials for weld neck flanges include:

Carbon Steel (ASTM A105, A350 LF2) – General industrial use

Stainless Steel (ASTM A182 F304/F316) – For corrosive or high-purity applications

Alloy Steel (ASTM A694 F42-F70) – High-pressure & low-temperature performance

Duplex & Super Duplex (ASTM A182 F51/F53/F55)– For extreme environments

Nickel Alloys (Inconel, Monel, Hastelloy) – Specialized industries like petrochemicals

Applications of Weld Neck Flanges

Our Weld Neck Flanges are widely used in critical sectors including:

- Oil & Gas: Offshore drilling rigs, refineries, and cross-country pipelines.

- Power Plants: High-pressure steam piping and cooling systems.

- Water Treatment: Desalination plants and large-scale irrigation.

- Chemical Processing: Handling corrosive fluids and high-temperature reactors.

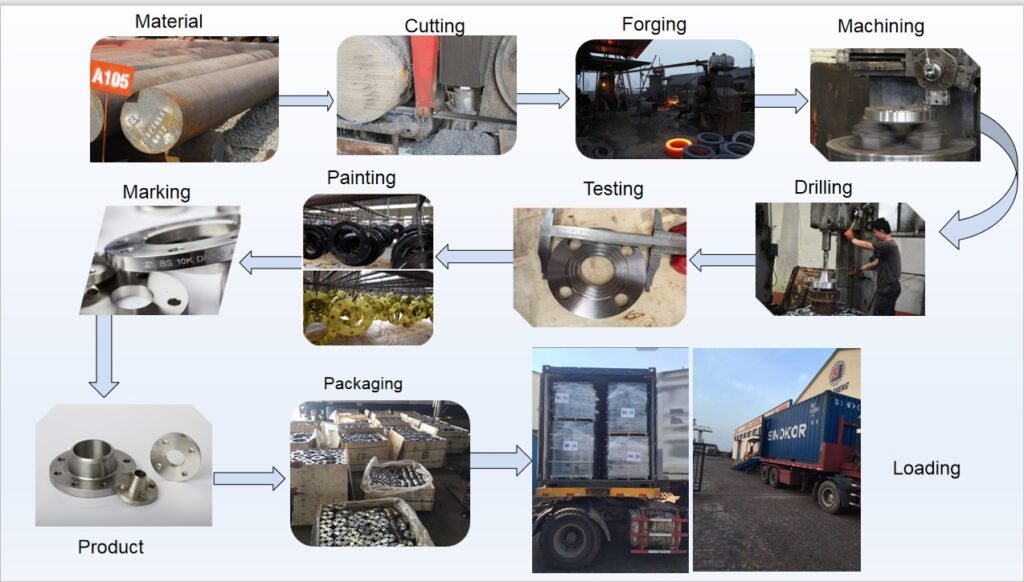

Manufacturing Processes

The forging process generally consists of the following steps:

- Selecting high-quality billet blanking

- Heating

- Forming

- Forging

- Cooling

Why Choose Rayoung Pipeline are your industry weld neck flange supplier?

- Precision Forging: All flanges are forged, not cast, ensuring no internal defects and a longer service life in high-stress environments.

- Full Traceability: Every flange is stamped with heat number, size, material, and pressure rating. We provide MTC according to EN10204 3.1 with every shipment.

- Strict Quality Control: 100% Dimensional inspection and visual testing. Ultrasonic Testing (UT) and Magnetic Particle Inspection (MPI) are available upon request.

- Global Standards Compliance: Our products strictly adhere to international standards like ASME, DIN, EN, and JIS, ensuring 100% compatibility with your existing piping systems.

- Fast Delivery for Stock Items: We maintain a large inventory of standard carbon steel A105 and stainless steel 304/316 flanges to support your urgent project needs.

Quality Assurance & Testing

To ensure the highest quality for EPC projects and terminal users, we perform:

- Chemical Analysis (PMI): Verifying material grade and composition.

- Mechanical Testing: Tensile strength, Yield strength, and Elongation.

- Hardness Test: Ensuring the material meets specific project requirements.

- Dimensional Check: Using calibrated calipers and gauges to ensure tolerance compliance.

FAQS:

Q1: What is the main advantage of a Weld Neck Flange over a Slip-On Flange?

A: Weld Neck Flanges feature a tapered hub that distributes stress more effectively, making them much stronger and suitable for high-pressure and high-temperature services where Slip-On flanges might fail.

Q2: Can you provide Third-Party Inspection (TPI)?

A: Yes, we welcome inspections by SGS, BV, TUV, or any other agency nominated by the client to ensure the products meet your specific quality standards.

Q3: What are the common facing types for WN flanges?

A: The most common is the Raised Face (RF). However, for high-pressure applications, Ring Type Joint (RTJ) is often preferred for its superior sealing capabilities.

Q4: How do you package flanges for sea freight?

A: We use export-standard plywood cases or pallets. All flanges are treated with anti-rust oil and protected with plastic caps on the ends to prevent damage during transit.

Cooperate with Rayoung, you will enjoy the following benefits.

Rayoung–A leading Butt Weld pipe fittings, flanges and steel pipes supplier& factory in China.

We’re here to help with your industry pipe fittings and flange needs. Rayoung has been in the business of industrial pipe fittings since 1983, and we’re confident we can help you find a solution more quickly, affordably, and with greater expertise than the competition.

We’d love to learn more about your project today!

Pre-sale Service

After-sale Service

Free Sample

Fast Quotation

Cerfifications

Test & Inspection

Customers say:

Talk About Your Needs

We respect your privacy and will not share your personal information with third parties or partners.