Spectacle Blind Flange

Sizes: 1/2″ – 96″ or customized

Rating Classes: 150#, 300#, 600#, 900#, 1500#, 2500#

Face Options: Flat, Raised, RTJ Male, RTJ Female

Material: carbon steel, stainless steel, alloy steel

Surface Treatment: General coated flange: Black Painting, Anti-rust Oil, red Painting, Gold Painting

Specially coated flange: Epoxy coated flange, Galvanized flange, PP coated flange

Standards: ASME B16.48, B16.47, B16.5, ANSI,GOST,EN,BS,SANS,DIN,JIS.

Production Description

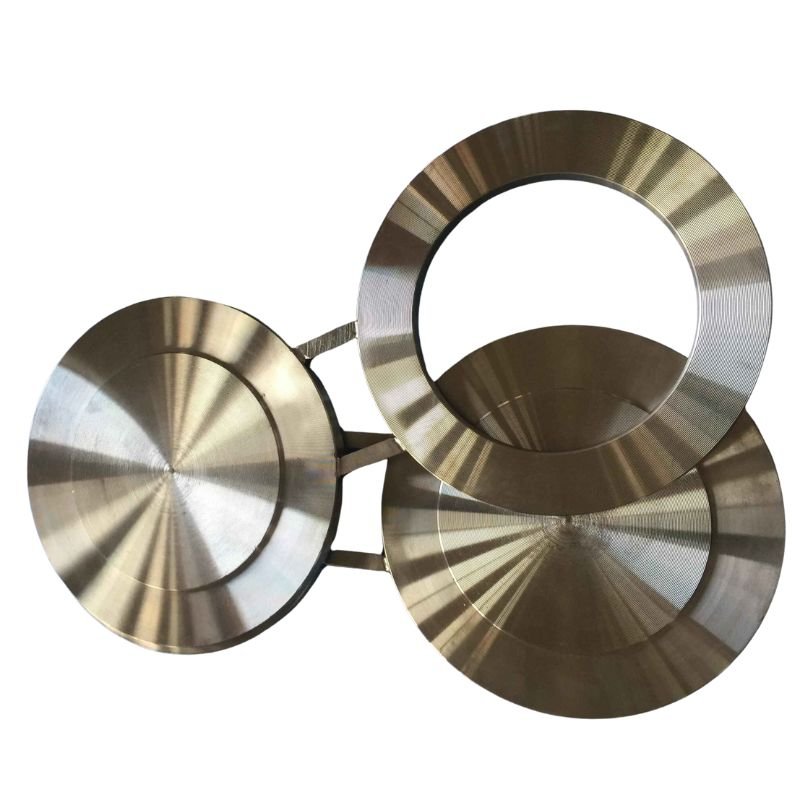

What is a spectacle blind flange?

A spectacle blind flange (or figure-8 blind) is a safety device in piping systems that looks like a pair of glasses, with one solid disc (spade) for blocking flow and one ring (spacer) with a hole for allowing flow, connected by a central handle, allowing operators to easily switch between open and closed states for maintenance or process changes without disassembling the pipe.

The Common Applications

The Spectacle Blind Flange finds versatile applications in various scenarios due to its reliable isolation capabilities and effective flow control. Here are its common applications:

2. Isolation of Flammable or Toxic Medium Pipelines: Ensuring safe isolation is crucial for pipelines carrying flammable or toxic mediums entering or exiting equipment. To ensure safety, double gate valves should be installed, with the Spectacle Blind Flange positioned between them, usually marked as normally open, for quick fluid shutdown in emergencies.

3. Control of Fluid Pipelines within Equipment: Within equipment, pipelines not requiring medium flow after normal startup should be controlled using gate valves, with the Spectacle Blind Flange installed on the side where the medium flows normally, typically marked as normally closed. This setup effectively controls medium flow, ensuring the safe operation of equipment.

Considerations for Selecting the Spectacle Blind Flange

When selecting and using the Spectacle Blind Flange, attention should be paid to the following aspects:

Sealing Performance: Consideration of the sealing performance of the Spectacle Blind Flange is essential to ensure effective leakage prevention during fluid shutdown, safeguarding the safety of pipeline systems.

Application Scenarios: Select the appropriate type of Spectacle Blind Flange, such as normally closed or normally open, based on various application scenarios, and arrange the pipeline system rationally to ensure its normal operation.

Explore Our Range of Industrial Pipe Fittings and Solutions

As a trusted steel pipe fittings and flanges manufacturer, RAYOUNG offers a comprehensive range of products engineered to meet international standards, including:

Standards Complied With:

ASME、ANSI,gost, EN, BS, SANS, DIN, JIS.

Material :

Carbon Steel (ASTM A105, A350 LF2)

Stainless Steel (ASTM A182 F304/F316)

Alloy Steel (ASTM A694 F42-F70)

Duplex & Super Duplex (ASTM A182 F51/F53/F55)

Nickel Alloys (Inconel, Monel, Hastelloy)

Coated flange:

General coated flange: Black Painting, Anti-rust Oil, red Painting, Gold Painting

Specially coated flange: Epoxy coated flange, Galvanized flange, PP coated flange

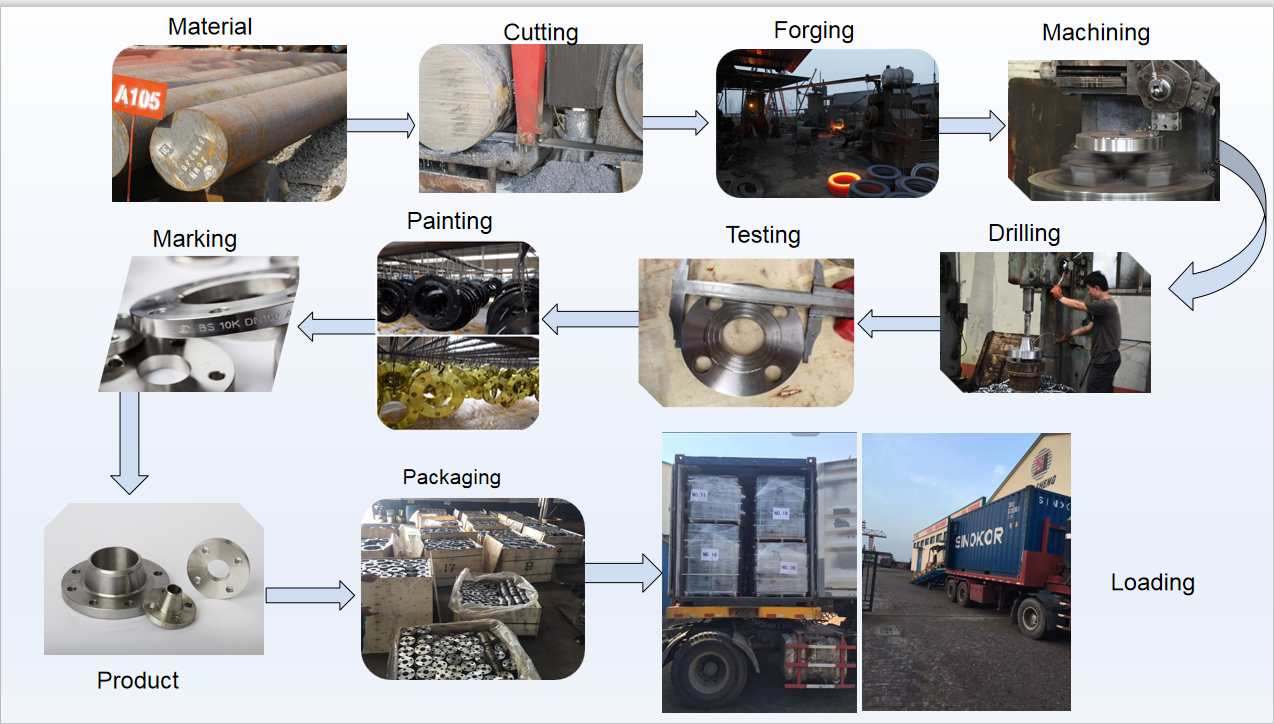

The production process of blind flanges:

Production of every flanges follows precise manufacturing processes to achieve leak-proof connections while strengthening durability and performance stability with high-pressure systems.

Cooperate with Rayoung, you will enjoy the following benefits.

Rayoung–A leading Butt Weld pipe fittings, flanges and steel pipes supplier& factory in China.

We’re here to help with your industry pipe fittings and flange needs. Rayoung has been in the business of industrial pipe fittings since 1983, and we’re confident we can help you find a solution more quickly, affordably, and with greater expertise than the competition.

We’d love to learn more about your project today!

Pre-sale Service

After-sale Service

Free Sample

Fast Quotation

Cerfifications

Test & Inspection

Customers say:

Talk About Your Needs

We respect your privacy and will not share your personal information with third parties or partners.